PEM®: Made In Europe, For Europe

PennEngineering: Accelerate your innovation.

Founded in 1942, PennEngineering® specialises in the design and manufacture of fastening solutions and installation systems. Operating across 20 global locations with a team of over 4,000 professionals, we focus on globally deployed capabilities, locally produced parts and close collaboration with customers. More the 10% of our workforce is comprised of qualified engineers, highlighting our commitment to innovation. This was recently recognised by Lean Business Ireland, declaring PennEngineering® as winner of the ‘Medium Lean Business of the Year 2023’ category.

PEM® Europe, headquartered in Galway, Ireland is one of PennEngineering®’s leading brands. From here, innovative fastening solutions and installation equipment is designed and manufactured for a range of industries, including Automotive Electronics, Consumer Electronics, Datacom, Telecommunications, Electric Vehicles and more. Through precision engineering, PEM® delivers cutting-edge products that improve efficiency, reduce costs, and enhance reliability in manufacturing and assembly processes.

“This award is a fantastic achievement and recognition of our commitment to lean excellence, and a testament to our culture of continuous improvement and innovation"

Mary Ann Fleming, President of PennEngineering® EMEA

PEM® Invented Self-Clinching Fasteners

Self-Clinching fasteners are designed to be installed into sheet metal and feature a unique design that allows them to be permanently embedded in a metal sheet, creating a strong, durable and flush attachment point. Fasteners are installed into a plain round hole without secondary operations required. They can be installed into dissimilar metals providing greater design flexibility and provide a clean, economical and environmentally friendly alternative to welding.

PEM®: Made In Europe: Made For Europe

Choosing products 'Made in Europe' brings significant advantages. Known for quality and craftsmanship, European fasteners and installation equipment present meticulous attention to detail, durability and superior standards. Moreover, they adhere to strict ethical and environmental guidelines, promoting worker safety and eco-friendly production methods. Supporting European manufacturing not only bolsters local economies, preserves jobs and fosters innovation, it also champions sustainability efforts, aligning with eco-conscious consumer priorities. The transparency of sourcing in Europe, for Europe and manufacturing processes, enhances consumer confidence, while reduced carbon footprints from shorter transportation distances speak to concerns about climate change, with the additional benefit of avoiding Carbon Border Adjustment Mechanism (CBAM) duty.

The European 'Right to Repair' (R2R) legislation aims to tackle the 'throwaway tech culture' by compelling manufacturers to offer consumers and third-party repair shops the tools, information, and parts needed for fixing electronic devices. This law is poised to revolutionize assembly methods, prolong product lifespan, cut carbon emissions, and minimize landfill waste. PEM® fastening products not only make assembly quick and easy, but they streamline disassembly too. This way, parts can be repaired, recycled, and reused much more easily. Many manufacturing processes that currently rely on welding, gluing, or sealing will benefit from PEM® fastening solutions that withstand R2R procedures.

PEM® is Carbon Border Adjustment Mechanism (CBAM) Ready:

The CBAM climate measure aims to address the risk of carbon leakage by ensuring equivalent carbon pricing for imports and domestic (EU) products that are subject to carbon costs under the EU ETS. Mary Ann Fleming, President of PennEngineering® EMEA comments, “At PEM® Europe, we embrace CBAM as an opportunity to further our dedication to sustainable production, fostering innovation, and contributing to a cleaner future for generations to come.”

Technical Services & PEMEdge™

Get Testing Support anytime, anywhere.

PEMedge™ Testing Service is an extensive set of in-house testing capabilities available under PEM®’s Technical Lab Services portfolio – at no additional cost to their customers. These testing services help customers meet industry regulations, develop new products, and evaluate the properties and limits of existing parts. These testing services are offered throughout Europe, providing global support at the local level.

- FEA Analysis

- Mechanical Testing

- Tensile and Compression Strength

- Hardness & Micro Hardness Testing

- Microstructural Analysis

- XRF Spectroscopy

- Fastener Joint Analysis

- Corrosion and Plating Testing

- Cleanliness Testing

Our testing is in accordance with:

- NASM 25027 & 45938

- ASTM A380

- AS9100

- ISO 9001 & 14001

- IATF 16949

- A2LA Certification

- QSLM Approval

Technical Cleanliness is a measure of the level of contamination of parts, including a particle size measure and an overall number and mass of particles measured. The PEM® Clean Lab was launched in 2020 and provides comprehensive cleaning and testing capabilities using the most advanced equipment in the industry. Clean Lab operations provide the ability to achieve technical cleanliness of PEM® fastening products per customer specifications and ISO 16232 and VDA volume 19 standards.

Ingress Protection Rating Testing

IP Rating Testing evaluates enclosures' protection for electrical components against foreign bodies (dust, dirt, moisture) by subjecting them to various conditions, and measuring their effectiveness in preventing intrusion. The Lab in Galway hosts state-of-the-art vacuum leak detection testing capability replicating IPX7/8 conditions.

PEMedge™ Teardown Service

Cut costs and improve assembly time with a free fastener analysis. Less hardware, More compact design, Lighter weight components, Streamlined, faster assembly, cleaner assembly/disassembly, cost savings

PEM® New Product Releases

The PEM® range of fasteners consists of thousands upon thousands of products, but these recent New Product Developments deserve a special mention:

PEM® CastSert™ Stainless Steel Press-in Inserts for castings and soft metals including aluminium and magnesium castings. Manufacturers working with die-cast alloys and soft metals now have an innovative, time & labour-saving solution to create strong, durable metal threads. PEM® introduces the 300 series stainless steel CastSert™ inserts, designed for quick, reliable, and cost-effective installations.

Precision Engineering for Efficiency: The PEM® 300 series stainless steel CastSert ™ inserts revolutionise installing durable threads into casted materials, offering a simple press-in technique. Unlike helical inserts that require panel preparation, CastSert™ inserts are installed by simply pressing into an ‘as-cast’ or drilled hole. This rapid installation method, using a flat punch and anvil, outpaces traditional methods by approximately 80%.

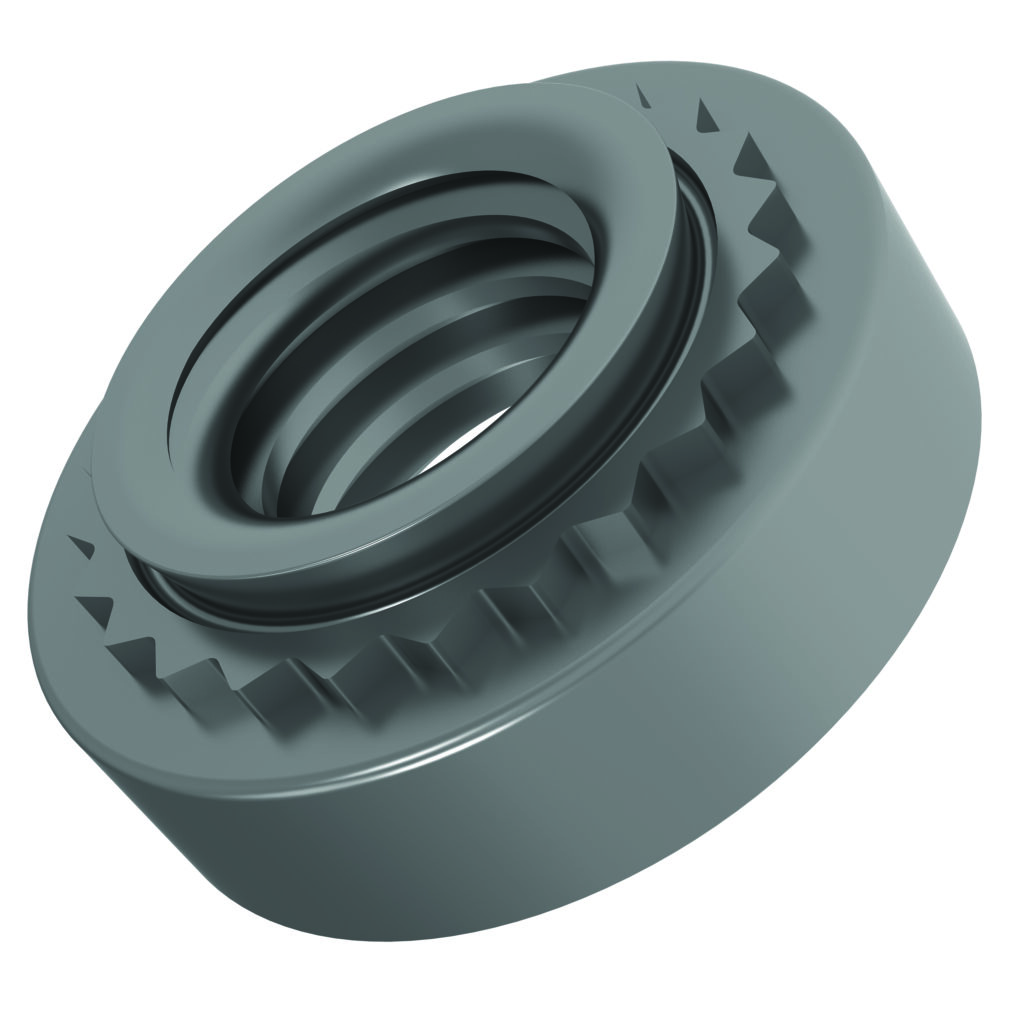

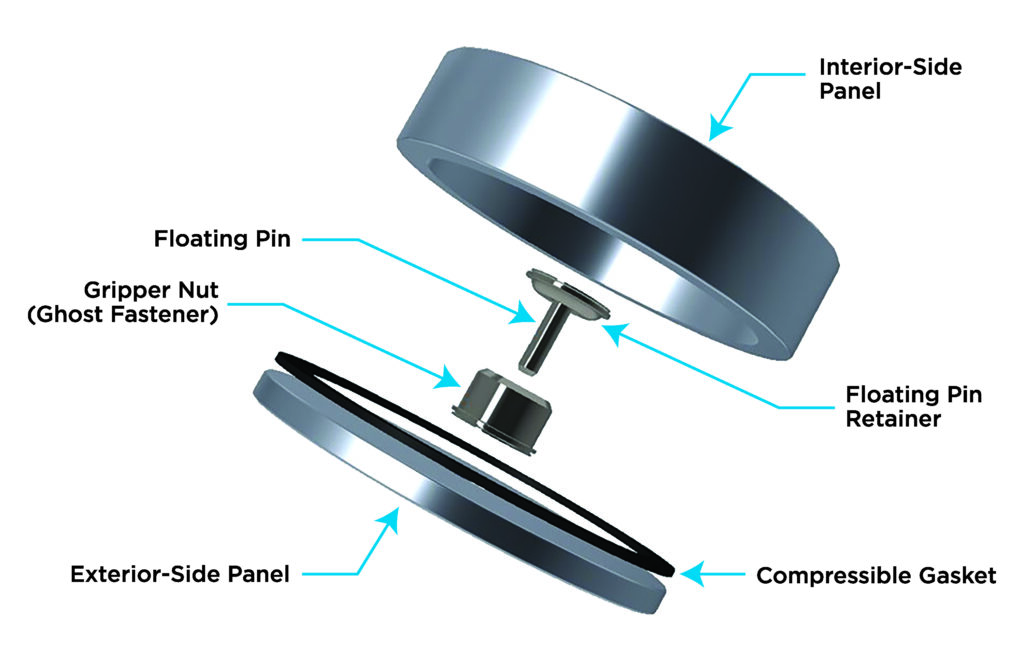

PEM® GHOST™ Fasteners provide a fully concealed fastener with zero visible evidence of how to disassemble, making it an ideal choice for industries that demand both sleek aesthetics and robust security. Only the user has the knowledge to disengage the fastener using a properly placed magnet or magnets. The gripping fastener utilises a fully concealed pinch-lock mechanism. A magnetic tool is used to actuate internal components, relieving the pinch-lock/grip.

PEM® expands its range of fastener offerings with the launch of RVTB™ threaded rivet bushes which create robust and reusable threads in ultra-thin panels, making them an ideal choice for a wide range of industries and applications. This addition solidifies PEM® as the primary destination for captive fasteners in thin sheet materials. Rivet bushes offer an advantage by enabling installation into high hardness panel materials. Their versatility spans across non-ferrous metals like aluminium alloy, copper, and brass, extending even to non-metallic materials.

PEM®’s commitment to ensuring joint integrity is emphasized by offering trust in the installation process. Utilising a Haeger® or PEMSERTER® installation machine for auto-feeding, meets the industry's demand for automated rivet bush installation. Notably, PEM® is the sole company in the market designing and manufacturing both the rivet bush and its specialized installation machinery, reflecting a comprehensive approach to meeting fabricators' needs and maintaining quality control throughout the process.

PEM® Growth Campaigns

eMobility: The electrification of transportation, often referred to as eMobility, is reshaping the automotive industry in unprecedented ways. Once dominated by mechanical engineers, the automotive sector now demands expertise in electrical engineering as vehicles transform into data-rich, smart machines. This shift is driven by consumer expectations, government regulations, and a desire for sustainable transportation options. PEM® plays a pivotal role in the eMobility revolution across EV battery trays, battery storage, charging stations, and 2/3 wheelers.

PEM®’s innovative solutions address key challenges, such as ensuring watertightness, managing weight, maintaining a low profile, ensuring strength, and meeting specific dimensions in battery tray design. These components are essential for the seamless operation of electric vehicles.

In addition to consulting, development, production, prototyping, testing and service, comprehensive support for customer-specific production planning, considering all the necessary building blocks for process-optimised automation technology, follows our goal of 360° connection technology.

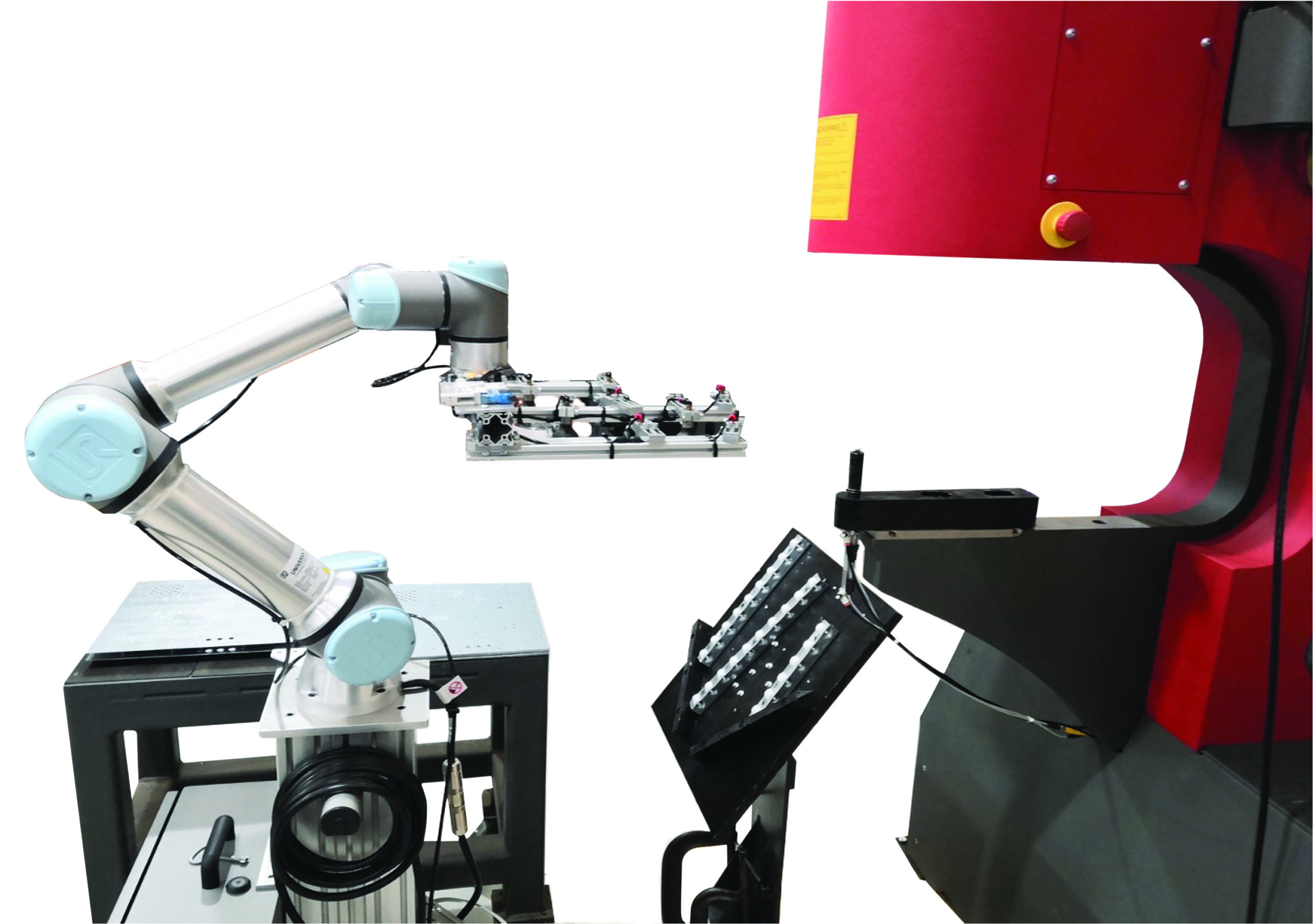

Better Together: Install Confidence and Optimal Production Performance with Haeger® Fastener Installation Equipment and PEM® Fasteners

In today's competitive manufacturing landscape, efficient fastener installation is pivotal. Haeger® Fastener Installation Equipment, known for automating installation processes across various materials, seamlessly complements the reliability of PEM® fasteners. This synergy enhances production efficiency, ensuring uniform placements and elevated product quality. The precision of Haeger® equipment aligns perfectly with the durability of PEM® fasteners, reducing downtime and operational costs. The ease of use and integrated software enables real-time monitoring, production planning, and data acquisition, promoting Industry 4.0 readiness. The technical service program HaegerCare™ provides comprehensive support, ensuring uninterrupted performance. The partnership between Haeger® and PEM® exemplifies a 'Better Together' approach, elevating manufacturing prowess.

2024: What’s next for PEM®

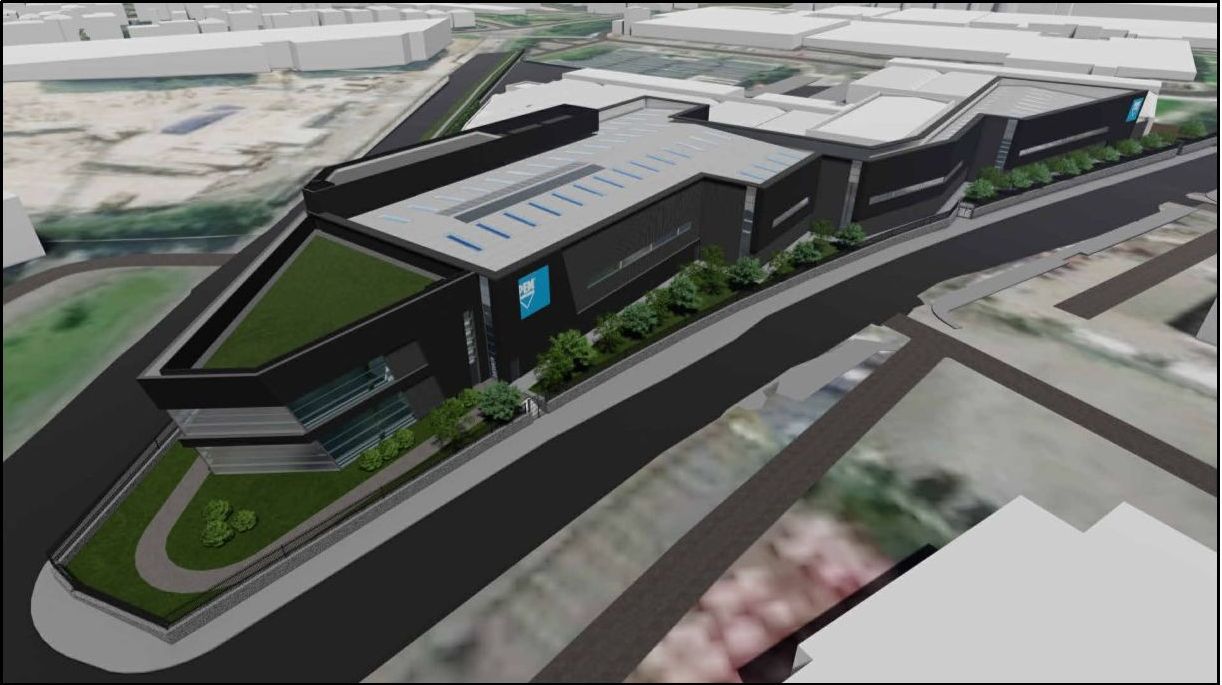

PEM® increases its presence in Europe with the development of a new 80,000² ft. facility located in Galway on the west coast of Ireland. The new facility will make the Galway site a ‘centre-of-excellence’ focusing on developing innovative solutions for the European market.

We've seen and solved 80 Years of Fastening Challenges: Your Success is Our Tradition.

"As we look ahead to the coming year, we acknowledge the challenges presented by uncertain market conditions and global turmoil. Despite these obstacles, we have secured many new projects for 2024 and our commitment remains unwavering: to pursue growth, adaptability, and innovation. We stand resilient, ready to navigate through these turbulent times, leveraging our strengths, and fostering a culture of perseverance and creativity. Together, we embrace the opportunities ahead, driving progress and achieving success."

Ger Quaid, Vice President of Sales and Marketing PEM® EMEA

Have a question?

Talk to an Engineer.

See what’s possible.

Connect with a PEM® engineering expert today and discover a reliable, cost-effective fastening solution for your challenging applications.

Fill out the form below or call/email us:

Email: [email protected]

Europe: 353-91-751714

U.S. 1-866-236-4063

China: 86-21-5868-3688

Singapore: 65-6-745-0660