Posted to News on 1st Jul 2025, 11:00

Delivering a clean energy retrofit: 800mm SAE 1 bellhousing for 250kW electric motor

jbj Techniques has developed a bespoke solution for a customer replacing a diesel engine with a 250kW, D355 frame electric motor on heavy equipment. Critical to this retrofit was the ability to interface the new motor with the existing SAE1/SAE14over-centre clutch, preserving the option to revert to diesel if required.

(See jbj Techniques at MachineBuilding.Live, 15 October 2025, on stand 101)

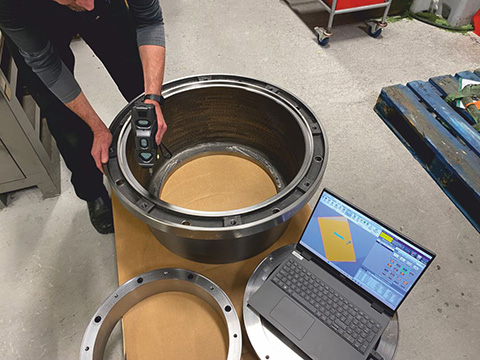

Working in close collaboration, jbj's design engineers and skilled machinists created a special 800mm diameter cast iron bellhousing to connect the motor flange to the clutch housing. The company also produced a custom coupling to convert the motor shaft to an SAE14" flange, enabling full mechanical compatibility with the clutch rotating group.

jbj's recently installed Puma V8300M CNC machining centre, with a 24" chuck and 800mm component capacity, proved invaluable for this large-format work. Aligning design with manufacturing capabilities from the outset ensured precision, efficiency, and a successful result.

Local sourcing, in-house capability

The raw casting, weighing 230kg, was poured at a trusted local UK foundry using pat-terns we own. jbj Techniques also designed and built all necessary tooling and handling equipment in-house. Coupling components were machined from locally sourced steel.

In-process inspection was streamlined using jbj Techniques' new Keyence XM-5000 handheld CMM system, allowing the company to bring the metrology tools directly to the component, saving time without compromising accuracy.

jbj Techniques' machine shop combines over 200 years of collective hands-on experience with a full suite of modern and traditional equipment, from state-of-the-art CNCs to manual lathes and even an anvil. This blend allows the company to support both bespoke, one-off jobs and large-scale production runs with short lead times.

This successful project has expanded jbj Techniques' capabilities and product range. The company can now offer fully UK-manufactured, low-carbon-footprint, cast iron bellhousings for D355 frame motors (800mm flange), available in standard lengths of 355mm, 380mm, and 400mm. Custom sizes also available on request.

28 Trowers Way

Holmethorpe Industrial Estate

RH1 2LW

UNITED KINGDOM

+44 (0)1737 767493