Posted to News on 17th Jun 2022, 14:16

All-in-one connectivity for motor power, signal and data

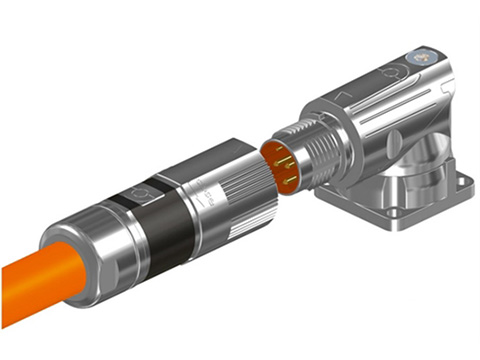

TTI is now stocking the Intercontec M12 one cable technology (OTC) motor connectors from TE Connectivity.

The M12 metal connectors with IP66/77 protection, when mated, are rated for 500 mating cycles, enabling robust and reliable installation of small servo motors for applications including automation, robotics, packaging, food and beverage, and material handling.

The new connectors have a maximum rated voltage of 630V (8-pole variant) and a maximum rated current of 8A. They also cover the digital transmission of 2- and 4-wire encoder protocols like Hiperface DSL, EnDat 2.2, ACURO link and SCS open link.

“With OCT solutions, using just one interface reduces the costs for electrical engineering on the servo motors as well as the expenditure for cabling in the application,” said TTI’s Markus Lorenz. “TE Connectivity’s Intercontec M12 motor connectors are key focus products. Especially as a one cable solution, the new connectors enable fast termination and the flexibility to save installation time and cost further.”

The M12 Intercontec crown clamp system offers 360-degree EMC shielding without cutting the braid to help save termination time. The Speedtec fast locking system saves installation cost and is backwards compatible with standard screw locking connectors; it is designed so that locking is only possible when the connector is fully mated. The rotatable angled housing enables easy adjustment of the cable outlet direction, even for the final installation position of the equipment in use.

Suite C, First Floor, Artisan Building

Hillbottom Road

HP12 4HJ

UNITED KINGDOM

+44 (0)1494 460000