Posted to News on 24th Apr 2020, 00:00

Automated fastening process: lean bonding

A new innovation from Bighead is Lean Bonding. “After several years in development, we are very excited to be releasing this major innovation onto the market,” commented MD Matthew Stevens. “Lean Bonding will remove many of the frustrations and difficulties in fastening lightweight composites and thin metals.”

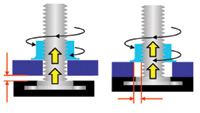

Lean Bonding is a fast, lean and automated way to bond fasteners onto composites. The solution consists of a bonding fastener pre-loaded with a dry adhesive film. This combination removes any need for separate adhesive storage, handling or dispensing. The fastener is bonded onto the surface in seconds, without any damage to, or penetration of, the material.

The combination of pre-applied adhesive and accurate process control ensures consistent bond line thicknesses and repeatable bond quality. Rapid green strength enables immediate part handling and minimises ‘WIP’. The entire process can be automated on a small or large scale. For smaller testing or prototyping volumes, a handheld bonding tool is also available.

In addition, Lean Bonding is available in different combinations of fastener and adhesive, giving designers and engineers freedom across a wide range of applications.

The development is the result of a multi-year collaboration with Cranfield University that was co-funded by Innovate UK, and involving a number of technology partners in the UK, France and Germany.

Unit 1, Black Moor Business Park

36A Black Moor Road

BH31 6BB

UNITED KINGDOM

01202 574601