Posted to News on 21st Feb 2016, 00:00

Breaking the buying cycle in power transmission component specification

Whether you’re building a prototype, starting a new production run or sourcing replacement parts, specifying power transmission components that integrate with each other, run reliably and fit to the necessary footprint can prove challenging. Once real life commercial considerations are also factored in it can be hard to identify the best solutions for any given project.

If you look back at buying trends for power transmission components prior to 2008, it’s quite easy to identify an attitude cycle that every few years shifted between ‘lowest possible purchase cost’ and ‘best quality, highest performance’. However, since the financial crisis, a new trend has emerged in which end-users are looking for the best ‘total cost of ownership’, looking for the component which will offer best value throughout its life in terms of cost and performance.

This shifting attitude should be seen as a positive step, not only for the end-user, but for the manufacturer and distributor as well. It rewards high quality engineering and reliable performance without placing too great a premium on brand recognition. At the same time, distributors who are able to speed up specification and guide end-users to the perfect solution are able to positively influence the total cost of ownership – meaning that they are able to add value to the components that they are selling.

In fact knowledgeable distributors can now play a greater part in the specification process than ever before, offering their expertise and understanding of different brands and designs to quickly lead the end-users to the best solution for them. Drive Lines Technologies is one such distributor which has developed a service which focuses on supporting the customer through from the initial enquiry to delivery, installation and beyond.

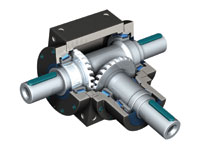

Drive Lines offers a range of power transmission components which span the entire drive train, with solutions for applications as diverse as high precision machine tools to heavy industries. Its rotary transmission components include MS Graessner and ZF Gearboxes, R+W precision couplings and torque limiters as well as a selection of brake and clutch components. It also boasts an extensive range of linear transmission solutions which include mechanical screw jacks, linear actuators and linear bearings that can be coupled with Exico electric motors and other accessories to create a complete lifting or positioning system.

Ian Carr, managing director, says: “We know which of our components integrate well with each other and we have the understanding of what’s possible in terms of system customisation.”

No engineer, whether they specialise in design, manufacture or maintenance can maintain an expert level of knowledge on all of the various technologies and designs that are being developed every day; nor should they be expected to. Businesses like Drive Lines Technologies are able to save engineers time and money and help to maximise the overall performance of any project.