Posted to News on 10th Jun 2025, 15:00

Camozzi Automation delivers plug-and-play pneumatic upgrade for leading kitchen manufacturer

When a leading kitchen manufacturer was struggling with a series of outdated pneumatic backplates which control their production lines of kitchen cupboard assemblies, it turned to Camozzi Automation.

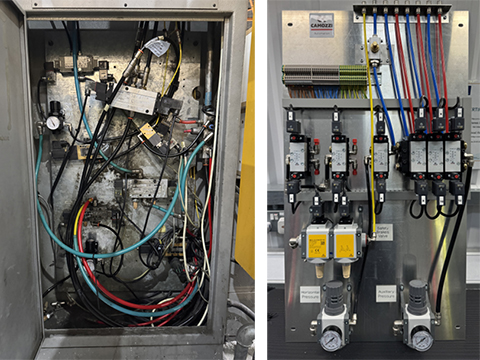

(Pictured: The panel before and after the pneumatic upgrade)

The kitchen manufacturer was finding that maintenance and fault-finding were challenging due to the absence of colour-coded pipework and a monitoring system. Health and safety were also a concern, as the original system had retrofitted safety components and lacked several key safety features.

One of Camozzi's premium distributors, Engineers Mate - part of the IADA group - approached Camozzi for support with the replacement of three initial backplates, one air preparation set and two valve control backplates.

Representatives from Camozzi Automation, including the technical application team, along with the distributor, visited the site to meet the team, understand operational and safety issues, and discuss the customer's requirements.

The customer required three complete backplate replacements, including new valves, colour-coded pipework to support fault-finding, and as many new safety features as could be recommended.

The application team at Camozzi Automation suggested the creation of a comprehensive operating circuit and full schematic drawings with clearly labelled valves to facilitate machinery maintenance.

The Camozzi technical application team began re-designing the backplates using the original machine manufacturer's documentation, incorporating the new safety and performance features discussed. The team had to work within a compact space and were provided with dimensions that the backplate needed to fit, including the positions of the mounting holes to ensure ease of installation.

Enhancements included colour-coded tubing to the customer's specifications, and dual Safemax MX monitored safety dump valves compliant with ISO 13849-1 (Performance Level e) to control rod lock devices on selected cylinders.

Camozzi also produced bespoke, dimensionally equivalent cylinders as a special order. These were manufactured in the UK specifically for the application, offering the customer a better-value alternative to the original manufacturer's components.

Once the design was approved, production commenced at the Camozzi Automation Centre.

The new Camozzi backplates were successfully installed, tested, and commissioned by the customer. Following the successful implementation, discussions are now underway to replace the remaining nine backplates across other machines and production lines, as well as additional pneumatic equipment.

The new panels and cylinders reduced air leaks, resulting in improved energy efficiency and associated cost savings.

The system was delivered as a plug-and-play solution and featured special cylinders to match the customer's existing non-ISO models - ensuring a smooth and disruption-free upgrade.

Rob Beech, Director at Engineers Mate, comments: "The whole engineering team were very pleased with the quality of manufacture and the ease of installation. Transitioning from the old, large panels to compact, well-laid-out new ones has been a great improvement."

The Fluid Power Centre

Watling Street

CV11 6BQ

UNITED KINGDOM

+44 (0)24 7637 4114