Posted to News on 26th Jul 2021, 00:00

Choosing the right conveyor belt for assured food safety

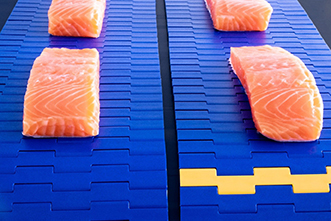

Running a food processing plant is not an easy task, not least because of the complexities of dealing with food safety and hygiene. Here Anna Marcol of conveyor and power transmission belt specialist Habasit, shares insights from a recent webinar delivered jointly by experts from Habasit and NGI, who discussed how hygiene-rated equipment and the right choice of belt type and material, are crucial in achieving food safety.

While food plant managers do a good job of keeping their facilities clean, food debris and microbes can still find their way into the smallest of dead spots. Bacteria can harbour on and in conveyor frames, under equipment, under the belt, or even in the small gaps of a plastic modular belt. What’s more, they can elude even the most rigorous cleaning cycles, leading to excessive use of detergent, water, time and energy.

So, evidently, food safety goes to the heart of the food process and supply chain. It’s also why food hygiene decisions made by food processors should be considered at each of the manufacturing, processing, and packing stages. Likely one of the most important pieces of equipment that runs through all these steps is the conveyor system.

When thinking about food safety and hygiene, food processing professionals should consider two key areas: hygiene-rated equipment and the right choice of food-contact elements, including belt type and material

Hygienic equipment

In open conveyor systems, food debris can contaminate surfaces and get into crevices and internal support structures over time. While an effective cleaning and sanitation plan goes a long way in reducing contamination, equipment and components designed specifically for hygiene can take less time, water and cleaning agents to clean and sanitise.

As such, equipment and components should be appropriately hygiene certified for food. This includes meeting minimum hygiene standards in accordance with the likes of 3-A, NSF or EHEDG guidelines for equipment, as well as being compliant with the food contact regulations by the FDA or EU 1935/2004, and other national regulations.

Hygiene certified components take into consideration among other factors the cleanability of surfaces, preventing ingress and the growth of microbes in dead spaces, self-draining surfaces or on levelling-feet or castors and much more. In any case, plant managers are required to care for equipment that is made from materials that are safe and do not change the composition of food, or its taste or odour.

However, these measures are only a means to an end. We wanted to share our experiences and participate in the dialogue on food safety, and so Habasit’s hygiene program manager, Bernd Roser recently delivered a webinar on food safety jointly with Niels Vindsmark, sales and brand owner program manager at hygienic component manufacturer NGI.

In the webinar Niels explained: “Applying hygienic certified components will not avoid an outbreak, but the more problems you can eliminate and the more certified hygienic components you have in your production facility, the less places you have to look at and worry about if you have an outbreak.”

Belting considerations

Bernd Roser pointed out that food plant managers should consider three areas when using open conveyor systems: choosing the right conveyor design, choosing the right food contact material to match the process conditions and selecting belts that support ease of cleaning. A conveyor design supporting sanitary needs is one that provides easy access to belting from all sides, to allow operators to inspect, clean, sanitise and validate effectively.

For example, Habasit’s Saniclip is a rod retention system with toolless belt opening that allows a line operator to remove and assemble a modular belt swiftly for easy cleaning.

When selecting the right food contact material, it’s important food processors choose a belt that doesn’t change its mechanical properties or wear quickly when regularly exposed to harsh, chemical-based cleaning cycles, at elevated temperatures and with extended contact times.

Easier cleaning

To support engineers in identifying the chemical resistance of various belt types and materials, Habasit has created a free online tool to help users decide the best belt for them. For applications exposed to very demanding hygiene conditions, Habasit has also developed Super HyCLEAN, a plastic modular belt that minimises the use of rods and hinges to aid cleaning, ideal for applications such as fish and poultry.

Whatever the food processing application, choosing the right conveyor belt, and ensuring equipment is designed with hygiene in mind is pivotal. Not only will it help food processors comply with industry standards, it will ensure the industry can continue to reduce the dangers of contamination – and make it easier for plant managers to run their facility.

Habegger House

Gannex Park

Dewsbury Road

HX5 9AF

UNITED KINGDOM

+ 44 (0) 333 207 6570