Posted to News on 24th Nov 2020, 00:00

Considerations for a linear guidance system

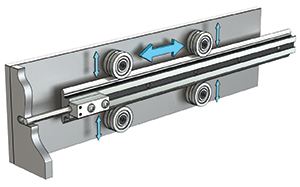

The fundamental element of any production cell is how to guide and transfer a component around the system. There are many options, each offering different advantages. When choosing which guidance system to specify, there are a few key aspects that should be taken into consideration. This article will consider recirculating ball bearing guide systems versus HepcoMotion’s V guide systems.

In order to achieve optimal performance from recirculating ball bearing guide systems, an absolutely flat mounting surface and the correct assembly of two parallel running rails are required. In most cases, this means longer installation times, as the assembly areas have to be prepared and the systems set in parallel. Typical manufacturer specifications show that the tolerance of the rail parallelism for a standard bearing (block size 25) with normal block preload is only 0.030mm over the entire travel distance.

Any tension or additional friction caused by assembly inaccuracies will very likely lead to a reduction in system life. The adjustment process for recirculating ball bearing guides can therefore be demanding and time-consuming, especially for longer length systems.

In contrast, HepcoMotion’s linear and ring and track systems with V profile guide technology can be mounted on minimally pre-machined surfaces thanks to their design. Furthermore, HepcoMotion’s axial compensation bearings allow assembly inaccuracies of up to 2.0 mm. HepcoMotion’s V guides can also be combined with standard flat guides and rollers, which allows even larger axial movements. When using linear guide systems such as HepcoMotion's V guides, assembly is less problematic and up to a few hours shorter. These time savings can be significant, especially on long production lines where several linear systems are used.

Maintenance and downtime costs

Perhaps even more important, however, is to take a look at the costs that can arise from maintenance and downtime. In the packaging industry, for example, downtime costs between £500 and £100,000 per hour are expected. Even where the costs are less significant, machine downtime is something that you want to avoid at all costs. It is therefore advisable to include any subsequent costs that may arise in the decision-making process.

When using a linear guide with a recirculating ball system, both components should be replaced in the event of wear due to the necessary precise fit of carriage and rail. Replacing the entire system, however, is time-consuming and means a longer machine downtime. This is different with HepcoMotion’s V guide system: here, play caused by wear can easily be eliminated by adjusting the eccentric V-groove bearings. Alternatively, the bearings can be exchanged quickly and easily. It is important that the rails do not need to be replaced because their service life is much longer, except for high-frequency short-stroke applications. For example, the four bearings of a normal carriage from the HepcoMotion GV3 system can be replaced in less than 10 minutes. On the other hand, it takes around 30 minutes to replace and readjust a complete recirculating ball system.

Of course, environmental conditions also play a role in the total cost of ownership and should therefore be included in the considerations for or against a recirculating ball system or a V guided linear system. In a recirculating ball system, if dirt or abrasion particles get under the seals or if they are damaged, the inner balls jam and the movement is disturbed. In extreme cases, this can lead to total failure - and to longer downtimes because, as shown above, in this case the entire system has to be replaced. In contrast to this, HepcoMotion’s V guide system has a ‘self-cleaning function’ due to the geometry of the contact surface between rail and bearing. In this way, dust, dirt and abrasion are simply constantly wiped off the running surface, and the system also works flawlessly in dirty environments.

Even when bearings have reached the end of their service life, they continue to function. Often, customers only notice that a single V groove bearing is worn out during the planned maintenance and inspection.

Installation time, initial conditions, maintenance costs and environmental conditions are certainly just a few factors that must be considered when selecting a system. What is clear is that it is important to look beyond the initial purchase price and consider the ongoing costs.