Posted to News on 22nd Jun 2022, 09:00

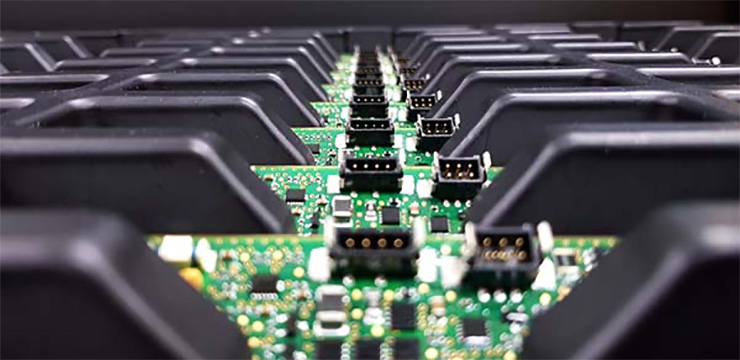

Corner and edge bonding and strain relief

When a PCB manufacturer was experiencing some inconsistency in manufacturing, specifically with corner and edge bonding, due to variability of the underfill process, it turned to Permabond.

In addition to increasing the reliability of the process, the company also wanted a solution that could be reworked. It came to Permabond with a ‘top ten’ product/process wish list, including:

- Easy to dispense

- No flow under components

- Fast cure

- No solvents – Low odour

- Reworkable

- Excellent shear strength

- High impact strength

- Bond materials with different coefficients of thermal expansion

- Vibration resistant bonds

- One product for edge bond and also strain relief

Permabond UV649 is a high viscosity, fast curing adhesive that forms strong, resilient bonds to plastics and metals, with many applications in electronics manufacturing. It is clear and colourless, which allows good depth of cure capabilities. The single-component adhesive is highly thixotropic – so it dispenses easily but does not flow after dispense. The reliable no-flow property ensures that the adhesive cures properly. If a UV cure adhesive flows under a component into an area shadowed from the UV light, it will not cure unless the adhesive has a secondary cure method.

UV649 is solvent-free, 100% solids, with minimal odour, improving workers’ comfort. With greater than 70% elongation, Permabond UV649 absorbs the stresses related to the differential coefficient of thermal expansion. Heating the adhesive over 100°C allows ease of removal for rework.

The manufacturer evaluated Permabond UV649 and found that in-line dispensing and curing simplified the edge bond process immensely. Instead of adding a separate, independent production line for the strain relief, the manufacturer added the strain relief dispensing into the corner / edge bonding automated dispenser, allowing for one UV cure cycle for both applications.

Using only one adhesive per production line reduces the chance of workers inadvertently using the wrong adhesive for each application. The versatility of Permabond UV649 makes it ideal for edge bonding, encapsulating, strain relief, and bonding applications in electronics manufacturing.

Permabond Engineering Adhesives Ltd

Unit 5, Wessex Business Park

Colden Common

SO21 1WP

UNITED KINGDOM

+44 (0) 1962 711661