Posted to News on 19th May 2025, 11:00

Cross Manufacturing Expands Metallurgical Laboratory Facilities

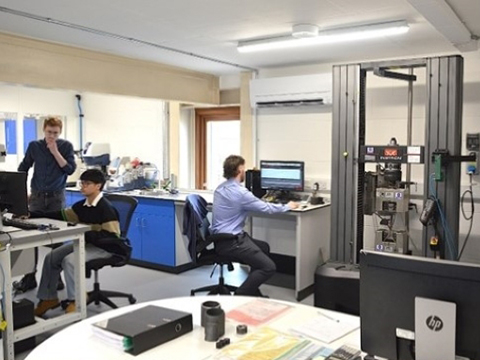

To meet the increasing commercial importance and demand for its activities, the Metallurgical Laboratory at Cross Manufacturing has moved into new dedicated facilities which will also enable further expansion in the future.

The fully NADCAP approved and accredited facility contains a comprehensive array of state-of-the-art test and analytical equipment. Routinely conducting extensive material testing, analysis and research, the department is dedicated to supporting production and customer needs, as well as researching, developing and implementing new materials and processes into production.

The Laboratory's metallography capabilities include the evaluation of microstructures for grain size, carburisation, weld analysis, corrosion, inclusions, defects, recast layers, fracturing/micro fracturing, coating evaluation, heat treatment, rolling effects and FMEA (Failure Mode and Effects Analysis).

Digital optical and scanning electron microscopes provide up to 60,000X total magnification, whilst a dedicated etching facility and modern semi-automated polishing and grinding capabilities allow for precise and accurate analysis at very high magnification, enabling comprehensive microstructural examination.

Microhardness testers, hardometers and tensile testing equipment enable full mechanical testing of materials at all stages of production in accordance with customer specifications including ASTM and NADCAP.

SEM-EDS (Scanning Electron Microscopy Energy Dispersive Spectroscopy) enables extensive chemical and elemental analysis of raw materials and products, allowing for material grade identification, contamination analysis, material heterogeneity analysis and more.

Mechanical testing at elevated temperatures using test furnaces, analytical equipment and software can test materials and products at very high temperatures for extreme lengths of time to simulate working conditions. Corrosion, creep rate, thermal dispersion, relaxation and more can be investigated.

Dr. Talha J. Pirzada, Research and Technology Manager at Cross, explains: "The Metallurgical Laboratory plays a critical role not only in maintaining the integrity and quality of our current manufacturing processes, but also in shaping Cross's future through research and development. By expanding our capabilities, we are better equipped to lead innovation in high-performance materials, explore emerging technologies, and collaborate more closely with customers on complex technical challenges."