Posted to News on 23rd Apr 2015, 00:00

Defining an entirely new class of drive system

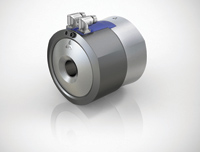

Launched at the Hannover Fair, Wittenstein says its Galaxie Drive System is a genuine world first, with vastly superior performance to other technologies. It's not simply that you get a hollow shaft gearhead with very high torque density, extreme stiffness and zero backlash in a compact design; Wittenstein says it also represents a completely new drive system with each tooth an independent and dynamic entity. Further, the drive has been fused with the newly developed high performance motor to form an ultra-compact, hollow-shaft drive system with integrated Industry 4.0 connectivity.

>At the heart of the Galaxie Drive System is the Galaxie gearhead. Where conventional gearhead have a typical linear gear tooth contact, the Galaxie transmits power via a ring gear which Wittenstein says generates significantly larger hydrodynamic surface contact. As a result, the Galaxie drive system can reach what Wittenstein describes as previously unattainable performance capabilities. This in turn opens up a host of high performance drive system possibilities for the manufacturing and handling technology sectors.

>Wittenstein says a 'no compromise approach was the guiding principle throughout the design and development of the Galaxie Drive System. Instead of constraining the design when technical challenges arose, the key performance characteristics were "optimised independently but realised in concert." The drive system boasts zero backlash, even at the zero crossing, while retaining full stiffness and no reduction in the transmittable torque. Wittenstein says the Galaxie Drive System has more than six times the internal hydrodynamic surface contact area of a traditional gearhead with the same outer diameter; this allows the Galaxie to achieve torque and stiffness characteristics many times greater than was previously possible.

>Characteristics and ratings compared with standard designs of comparable size include maximum torque

>70-150% higher, emergency stop torque 150-300% higher, torsional rigidity 340-580% higher, and efficiency 18-29% higher. In specific applications, this might mean that DMT lathes can achieve much shorter feed-through times and longer-lasting tools; in spline rolling machines Galaxie could reduce vibration and almost halve the main machining time; and in riveting systems the drive system could noticeably reduce the rivet head decay times and result in highly dynamic axes.

>Wittenstein Galaxie Drive System designer Thomas Bayer says: "These are real, verifiable results that have been reported to us by our customers." Further, through testing with these customers, Bayer confirms that the gearhead is virtually wear-free. "Even after running for two and a half years, it shows no increase whatsoever in backlash. With no wear, it remains backlash-free. What's more, Galaxie combines the largest hollow shaft with a very low noise level that isn't perceived to be a nuisance. And to get the same torques as we do with Galaxie, we'd have to build any other type of gearhead at least two, if not three, sizes bigger.

>The key to the performance, Bayer explains, is in the gear tooth design. "The majority of teeth on a gear only rarely engage - they just turn idly. Involute teeth make linear contact, which severely limits the transmissible torque. The logarithmic spiral in the Galaxie is a fundamentally new function for gear teeth that was discovered and developed by us. It has yet to feature in any textbook. The gearwheel is segmented into individual teeth which means that almost all of them engage simultaneously."

>Thus the gearhead dispenses completely with a gear wheel - instead, each of the 24 teeth involved in torque conversion is an independent and dynamic entity, which is supported by a needle bearing, grouped and guided along the teeth of a ring gear. The tooth contact is no longer a line, but a surface. It is the combination of multiple teeth and surface contact, plus the hydrodynamic lubrication film built up by the teeth in contact, that leads to the unique specifications.

>At Hanover Wittenstein also offered insight on how the Galaxie Drive System fits into Industry 4.0 scenarios. A key prerequisite of Industry 4.0 is the cross linking of drive systems with people and system environments, and the Galaxie Drive System can fulfil this role.