Posted to News on 1st Mar 2022, 16:30

Dynamic drive controllers optimise performance of shredding machines

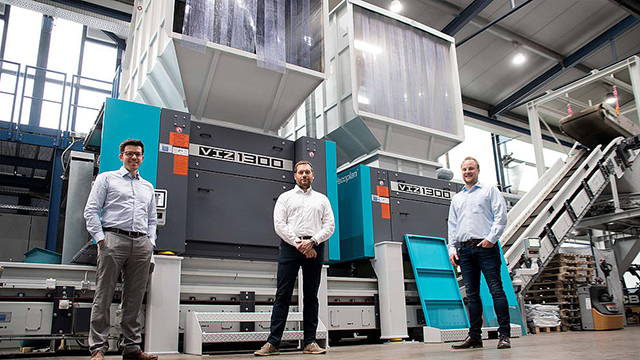

KEB Automation has supplied drive controllers, mains filters and chokes to Vecoplan, a specialist manufacturer of shredding machines used by the recycling industry. The COMBIVERT F6 drive controllers from KEB were selected due to their ability to deliver high performance dynamics under harsh machine operating conditions.

Based in Bad Marienburg in Westerwald, Germany, Vecoplan is one of the leading manufacturers of machines for shredding, conveying and processing of wood, biomass, plastics, paper and waste.

The shredding and processing of materials requires systems that deliver top performance even in harsh conditions. At the beginning of the recycling process, the environment is dusty, wet and sometimes noisy. As the materials to be re-used must be shredded, this requires machines, equipment and components that are not only efficient, but extremely robust.

Working in these harsh conditions places high demands on Vecoplan’s shredding machines, as well as the machine’s components. With this in mind, Vecoplan opted for drive controllers from KEB. In this specific case, the COMBIVERT F6 drive controller delivers an output of up to 315 kW. Matched mains filters and chokes from KEB complete the requirements within the system.

The selection of the machine’s individual components was guided by the objective of making the shredding machines more dynamic. The shaft of the shredder should be able to maintain speed at all times. After all, even with high loads and a demanding operating environment, there should be no blockages in the shredder, as any machine downtime is costly.

“In the recycling industry, we often find environments with a very high dust load. This can quickly lead to damage in plant machinery. In order to prevent this error-proneness and to increase the degree of protection, the circuit boards in our drive controllers, for example, are given a special coating that ensures greater robustness,” explains Malte Habbishaw, sales engineer at KEB Automation.

For machines and systems in the recycling industry, KEB has been supplying all the necessary products from a single source for more than 15 years. For example, complete control cabinet solutions are available to ensure direct and trouble-free use.

“We have products with up to IP66 protection class. This makes our drive controllers ideally suited for use in particularly humid or dusty conditions,” says Habbishaw. Another advantage with KEB is that its braking resistors are integrated directly in the drive controller. This means noticeable space savings and less wiring effort. This is also an important factor for Vecoplan, as their head of development, Martin Baldus states. After all, it is important to keep the control cabinets as small as possible.