Posted to News on 24th Feb 2021, 15:20

The current view on electrically conductive adhesives

Electrically conductive adhesives are now commonplace and have contributed immensely to the micro design of everyday consumer electronic devices. iPads, mobile phones, medical devices, flexible PCB's, wearable conductive clothing, RFID tagging and RFI shielding are just some common applications with which we are all familiar. In this article, Simon Dearing, Managing Director of Eurobond Adhesives, reveals more about the technology and how to use and maximise it

There are two types of electrically conductive adhesives: isotropic and anisotropic. Isotropic conductive adhesives (ICA) are electrically conductive in all directions and are used in applications such as chip contacting and the bonding of electrically conductive SMDs.

Anisotropic conductive adhesives (ACA) contain special conductive particles in the µm range, which conduct electricity in one direction only. These adhesives are used, for example, in many sensitive structures on circuit boards, such as LCD connections or contacting flexible PCBs, or for bonding antenna structures on RFIDs.

Today, the range of conductive adhesives and their applications is both vast and varied. Conductive adhesives are tailored to suit almost any application and are formulated as either one component products that are thermally curable, or two component products that when mixed together cure at room temperature. For a faster cure time they can be thermally cured. When selecting the right adhesive for a specific project it is important to consider the following points whihc can be discussed in depth with a specialist adhesive technical adviser from Eurobond:

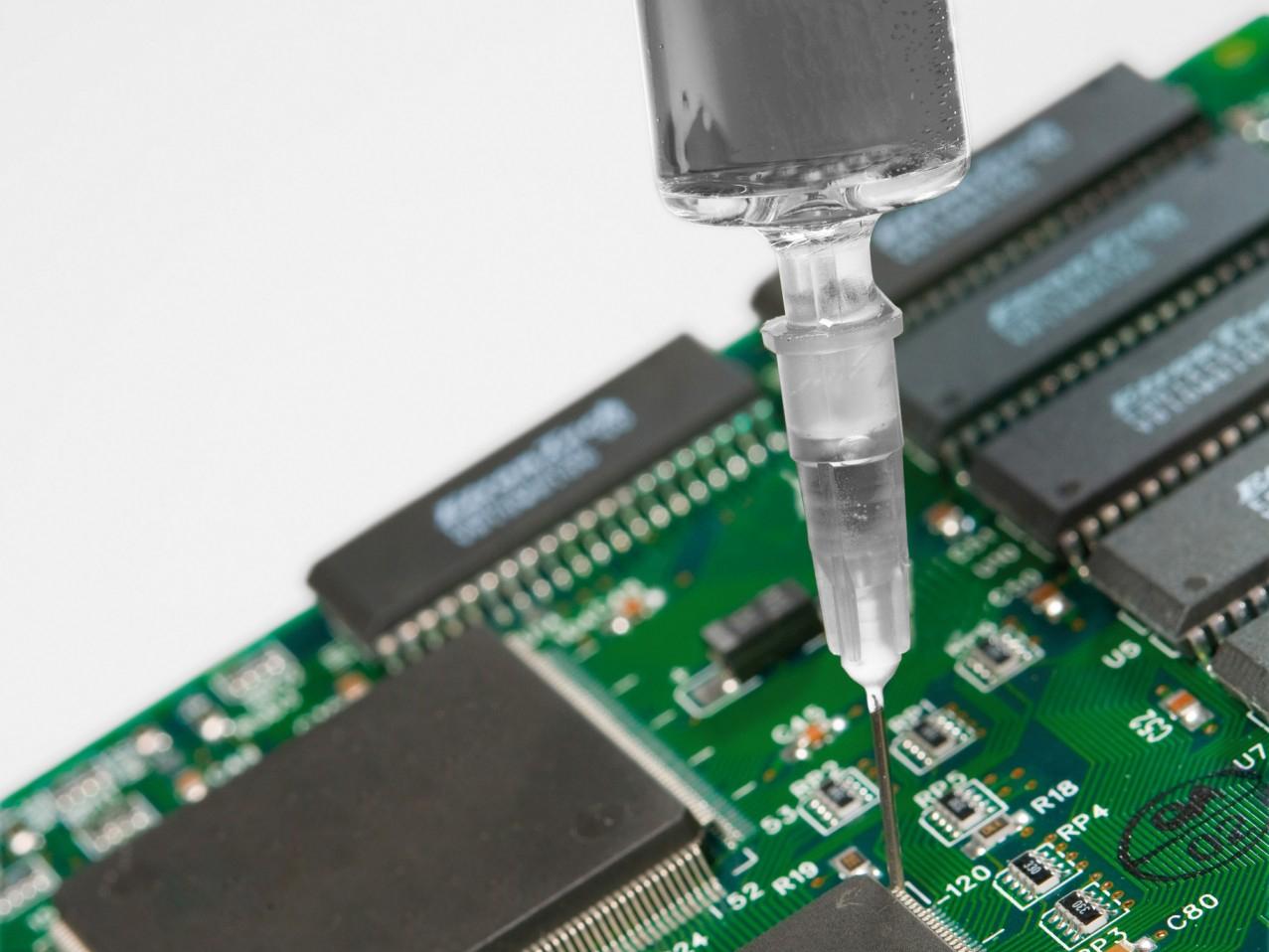

What type of dispensing method will be employed: for example syringe, stamp, screen print or jet?

The type of filler required: for example Silver, Copper or Graphite?

Does one specify a paste or a liquid adhesive single or two component product?

Does the application need an Isotropic or Anisotropic adhesive?

What pot life best suits a given application?

What cure time and cure method will be employed?

What volume resistance does the application require?

What coefficient of thermal expansion can the project accommodate?

Eurobond offers the Elecolit® range of silver filled, one-component adhesives that can be simply applied with dispensers, jets or screen-printed, as well as two-component products that cure at room temperature and have a long pot and storage life.

Innovative hardener systems in many of the one-part epoxy based adhesives develop to a ‘cure’ within minutes and these can be used to connect heat sensitive components to printed circuit boards, wave guide plumbing, hybrid circuit assembly, connecting ground wires to components, making conductive tracks or pathways and bonding discrete devices and hybrid circuits. Other applications include bonding conductive paths in heated car windscreens and mirrors, RFID applications, bonding batteries to foil/film, bonding flexible film LCD’s to hard FR4 boards, circuit track repairs, populating PCB’s: the list is almost endless.

Here at Eurobond Adhesives we offer a select range of both one and two component electrically conductive adhesives and electrically conductive adhesive tapes. Our high quality technical tapes have been developed for a range of applications in the electronics industry including masking, EMI/RFI shielding, PCB masking, conductive connection and fixing, anti-static and wireless power charging.

Elecolit® 325 is a two component pure silver filled epoxy adhesive which combines the excellent adhesive properties of the epoxy with the electrical conductivity of pure silver. It is easy to use because equal amounts of Part A and B (resin and hardener) are mixed together and it has a 1 to 2 hour pot life. Elecolit® 325 may be processed with dispensers, stamps or by screen printing. Curing occurs at room temperature. Increasing the temperature speeds up the curing process. Elecolit 325 has excellent gap fill properties too.

Applications

1. Connecting heat sensitive components to printed circuit boards.

2. Bonding wave guide plumbing, hybrid circuit assembly.

3. Replace metal solder where temperature or convenience in the application is required.

4. Chip bonding for discrete devices and hybrid circuits

Elecolit® 414 is a polyester – based, electrically conductive ink, coating and adhesive suitable for application by stamping, screen printing, dipping and syringe dispensing. Elecolit® 414 is formulated to provide exceptional conductivity when cured at low temperatures. Unlike conventional conductive materials, this product is very resistant to flexing and creasing. Some applications for Elecolit® 414 include, but are not limited to, EMI/RFI shielding of polyimide flexible circuits, polymer thick film circuitry, membrane switches, electrical attachments for surface mounted devices and anode coatings for tantalum capacitors.

Elecolit® 3653 is a silver filled, highly flexible solvent free conductive adhesive. The flexibility of the cured adhesive makes it ideally suited for applications which involve vibration or thermal shock. The product can be dispensed or processed with stamp, print or screen print. Elecolit® 3653 is a one component product, thermally curable in short time frames.

Elecolit® 342 is a 1K silver-filled electro conductive coating with excellent glass, metal and plastics bonding properties, which cures to a hard film in the air. It can be processed with brushes, dispensers or via needle transfer. Electrical conductivity is excellent. Elecolit® 342 has excellent glass bonding properties and is, for example, being used to create windshield defroster contacts in cars, or RFI shielding of electronic housings. After extended storage periods, the product must be re-homogenized as it sediments naturally in low viscosity resins.

Bonham Drive

Eurolink Industrial Estate

ME10 3RY

UNITED KINGDOM

+44 (0)1795 427888