Posted to News on 31st May 2022, 12:11

Encoderless and safe control of drives via Profinet

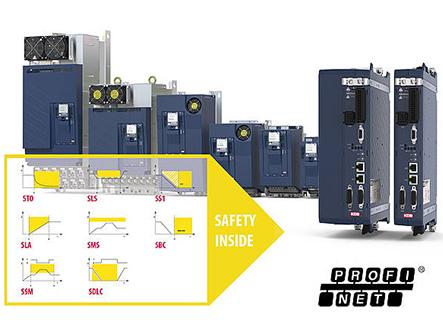

Safety functions without encoders reduce costs and increase process and machine safety. COMBIVERT F6 drive controllers and COMBIVERT S6 servo drives from KEB Automation are now certified in the device variant ‘PRO’ for communication via the real-time Ethernet interface, Profinet.

For the automation of their systems and processes, this means users have another standard available to implement concepts with encoderless safety.

Functionally safe system solutions for machines and plants are based on a consistent architecture right down to the mechanical interface. This results in potential savings in terms of space, time and costs, as well as expanded possibilities in application. Certified hardware and software are used to simplify project planning and development of applications with safety solutions.

KEB drives offer scalable safety functions directly in the drive controller. In the PRO device variant, the COMBIVERT F6 and S6 enable the implementation of encoderless safety. Here, a flexible adaptation of the safety functions and limit values can be carried out via digital IO. Up to eight safety configurations are possible per function. The COMBIVIS 6 software tool from KEB enables customers to easily commission the various systems.

The COMBIVERT F6 and S6 series cover a wide power range from 0.75 kW up to 450 kW and can be used to operate different motor technologies such as asynchronous, synchronous, synchronous reluctance, IPM, torque, linear and high speed motors with speeds up to 45,000 rpm. The safe encoderless speed monitoring function can be used independently of the motor used and therefore for a variety of applications. Here, different installation and cooling versions ensure a high level of scalability in the application.