Posted to News on 9th Aug 2022, 08:29

Essentra Components cuts energy usage by 15% globally

An innovative energy reduction initiative based on the concept of insulated jackets is helping industrial components manufacturer Essentra Components cut its energy usage when heating machine barrels by 15% and save CO2 emissions in the process.

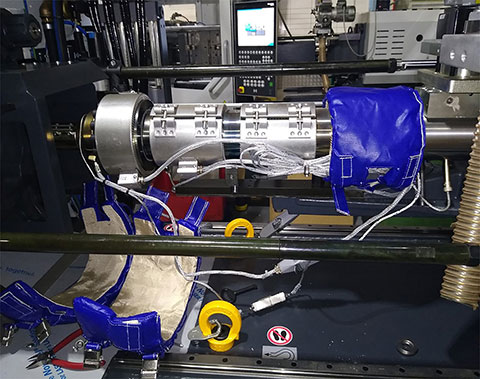

As a programme, some 347 injection moulding machines will be wrapped in custom made heat jackets made from high efficiency insulation to reduce heat loss in the extrusion barrels. Almost 300 machines have already been fitted with jackets and as a result Essentra Components has seen a 15% reduction in energy usage per machine, when its barrel is heated.

The new heat jackets are installed in sets of three across the barrel and reduce heat loss per cycle across the machine. They also reduce the amount of energy needed (by 0.4kWh of electricity) to reheat the barrel for the next cycle. Not only will it increase efficiency, but the jackets will also reduce the external guard temperature by 30%, decreasing the risk of burns.

Overall, current data shows the jackets are saving Essentra Components £400 per year in the UK, across 7,000 hours of manufacturing per machine, whilst costing just over half of that figure to install. The initial investments have already been paid back with a return on investment of just 0.6 years.

In addition to cost and energy savings Essentra Components expects the jackets to extend the lifespan of its newly replaced electric machinery as well as reducing CO2 emissions. At its Flippin Arkansas location, 83 machines have already been fitted out and are expected to shed 654 metric tonnes of CO2 annually.

Richard Sederman, strategy and M&A director at Essentra Components said the initiative is one more step in Essentra’s journey to carbon neutrality: “As a business we’ve set ourselves the goal of achieving carbon neutrality by 2030. To do that it takes many small yet critical innovations like these heat jackets to make the incremental steps needed to reduce our carbon output.

“The results we’ve seen so far are impressive in comparison to the extremely low installation cost. Not only will it reduce our energy usage and carbon output, but it will keep our team safe. In truth it’s a ‘win win’ solution to a very challenging problem.”

Chris Butler, divisional engineering manager, added that the programme will also extend machine life, vital for green manufacturing: “In recent months we’ve accelerated the installation of new electric machinery. These new heat jackets will allow us to not only make those machines more efficient but extend their life cycling helping use reduce wastage and carbon emissions, ensuring these machines continue to run for years to come.”

The final stage of installation will see the last 52 machines fitted with heat jackets in Rayong Thailand. By project end, Essentra Components will have installed 1,041 of the energy jackets across all of its injection moulding machinery.