Posted to News on 3rd Jan 2007, 00:00

Flexible couplings cut vibration at grinding mill

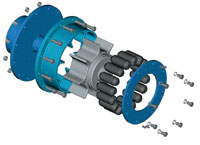

Renold Hi-Tec Couplings has worked successfully with a mining company in Australia to reduce a problem it was experiencing with extreme vibration in the drive train of one of the biggest grinding mills in the world. The autogenous mill for grinding nickel ore is powered by two seven megawatt electric motors that drive a 9.6 metre diameter shell with a 12.1 metre diameter girth ring. The mill grinds the nickel ore within a rotating drum that propels material in a cascading motion causing impact breakage of larger rocks and compressive grinding of smaller particles.

Renold Hi-Tec's engineers analysed the levels of vibration and recommended the use of two PM600 rubber-in-compression couplings with specially selected rubber blocks. The two couplings, located between two reduction gearboxes and the girth ring pinions, deliver 200kNm at a speed of 170rpm and have completely resolved the problem with vibration.