Posted to News on 14th Mar 2022, 11:00

Futureproofing your operations with cobots is easier than you think

Automated shop floors where cobots work alongside operators are no longer the future, but rather the present. Whether they are used in manufacturing packaging, warehousing, maintenance or training – collaborative solutions are already changing the way we operate and, ultimately, the industrial world we know. Easy to program and install, they are also ideal for entry-level automation applications.

Barry Weller, robotics product manager at Mitsubishi Electric, looks at the benefits of implementing collaborative robots and how easy they are to integrate into existing processes.

Collaborative and industrial robots are increasingly used in a wide range of industrial activities. In a decade, the global sales volume of industrial robots tripled, with up to 422,000 units shipped worldwide every year. Cobots represent nearly 5% of this total – a portion that continues to increase annually.

The high adoption rate for robotic solutions is primarily driven by the vast benefits they can deliver. Robots improve productivity and throughput while delivering high accuracy and reproducibility, leading to consistent production quality.

Collaborative robot solutions are particularly attractive, as they typically require smaller initial investments. They are also easier to fit into existing manufacturing setups, as no physical barriers are required to ensure a safe working environment. One of the biggest advantages, however, is how intuitive and easy they are to use and interact with.

Making programming instinctive

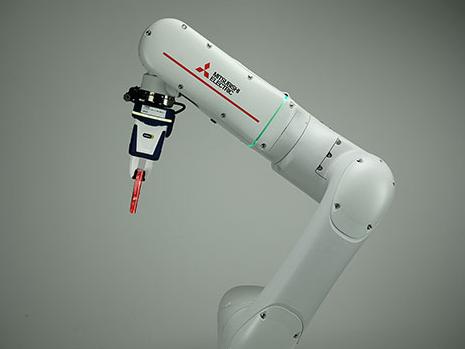

Cobots utilise visual programming languages and graphical user interfaces that let users sequence the process and manipulate key functions without any coding. This significantly reduces programming complexity. For example, Mitsubishi Electric’s MELFA Assista cobot is coupled with an intuitive, touch-enabled engineering software, called RT VisualBox. This software supports the creation of operating sequences by linking block diagrams in a chain of events.

External devices, such as vision systems, can be connected to the cobot by using a software wizard within RT VisualBox that guides them through each step of the setup process. It is also possible to automatically perform key functions, such as the calibration of a coordinate system using Artificial Intelligence (AI).

To make things even easier, the MELFA Assista offers an additional hand-guided teaching function. With it, the cobot can be manually guided into a position, which is then added to the work sequence by pressing a button on the robotic arm.

These functionalities help operators create even highly sophisticated applications without any prior programming knowledge. Installation and setup can be streamlined and businesses can start using them almost instantly. These elements are also extremely helpful to companies at the beginning of their digital transformation journey and help users grow their confidence and skills in factory automation. There is no need for operators to have a high level of expertise in robotics or programming.

This also helps companies to develop their own in-house expertise and evolve over time, which can then support the use of more complex solutions, such as conventional industrial robots. Ultimately, businesses can increase their automation literacy and create highly effective setups that meet their specific needs and requirements.

Futureproofing education

Finally, the ease of use of a cobot such as the MELFA Assista can be key in meeting the current and future workforce training requirements. Being able to work with robots and all other automation components that make up smart factories will be a key requirement for the plant engineers of tomorrow. This means being able to set up these machines, interact and inspect them as well as conduct maintenance activities.

Improving skill provision systems and upgrading education policies to advance technology skills is therefore becoming increasingly important. To address these educational needs, Mitsubishi Electric provided Redcar and Cleveland College with an RV-F series articulated arm robot. The setup gives pupils the unique opportunity to develop key skills in a hands-on learning environment. They are able to develop practical skills, such as programming different axes of motion themselves, and gain an understanding on how to deploy and maintain robots.

Collaborative robots can further support this development, as they remove entry barriers and contribute to increased ‘robot literacy’ across the workforce. By implementing cobots, forward-thinking businesses can benefit from automated processes and also support their staff in developing key skills, adding value to their operations in the long run.