Posted to News on 22nd Sep 2021, 00:00

Igus now offers injection moulded, cost-effective production of lubrication-free gears

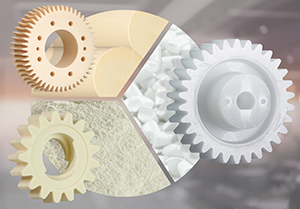

Gears made of polymer deliver power transmission in many applications, from automatic coffee machines to actuators. Specifically for producing wear-resistant and durable gears, Igus now offers injection moulded gears in addition to machining from bar stock and those made using additive manufacturing (3D printing). Customers can select from a large standard range of lubrication-free iglidur materials from Igus.

Polymer gears are becoming increasingly popular because, compared to metal alloy gears, they require no lubrication and are therefore maintenance-free. In addition, moving polymer parts are quiet and are often lighter than metal. Igus has supplied wear-resistant gears made using 3D printing as well as machined gears made from iglidur bar stock for several years. For the economical production of high volume gears, the motion plastics specialist has now expanded its range to include injection-moulded gears.

“By using injection moulding, the customer can now obtain their gear from our wide-ranging material varieties,” explains Steffen Schack, head of the new iglidur gear business unit. “Straight from stock, we offer injection-moulded gears made of the materials xirodur B180 and iglidur F, each in three designs.” The material xirodur B180 is a wear-resistant endurance runner and dampens vibrations. iglidur F also has a long service life and is suitable for applications with high temperatures. In addition, it is electrically conductive.

The Igus gears developed so far from the iglidur high-performance polymers have a significantly longer service life than gears made from standard plastics. At the company’s 3,800m2 research laboratory, Igus subjects its injection moulded, printed, and machined gears, made of all Igus materials, to rigorous testing. Tests showed that injection-moulded gears made of the material xirodur B180 have a four-times longer service life than gears made of the standard POM polymer.

Depending on the configuration and specific application, Igus now offers manufacturing in three different processes: for fast delivery of wear-resistant customised components within a few days, 3D printed gears made from the laser sintering material iglidur I3 is the process of choice. Machining from iglidur bar stock, for example, is suitable for producing gears in medium volume. Injection moulding, on the other hand, offers the greatest iglidur material variety and, above all, cost-effective batch production of special dimensions.