Posted to News on 10th Jun 2025, 10:00

IMI boosts uptime and efficiency at Chinese plant with 3D printed valve trim

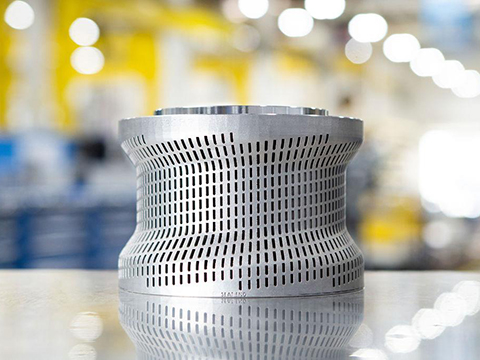

In an APAC first, eleven 3D printed valve trims, complete with ABJ soft seat, engineered by IMI have boosted uptime and efficiency at a Chinese power plant at substantially lower cost than a full valve replacement.

The existing valves had become inefficient due to severe erosion and leakage caused by insufficient pressure reduction. This would typically require considerable opex and capex investments because of both the cost of a replacement valve and the extensive engineering involved in its installation.

IMI's Retrofit3D solution involves the engineering of bespoke drop-in replacement internal components with substantially upgraded performance. This includes both the valve trim and seat, meaning the valve casing can remain in place. Replacement parts are custom-made to the specific process conditions of the valve, far more quickly and at a lower cost than would be the case with conventional manufacturing methods.

In the case of the Chinese installations, the replacement valve trim also included a soft seat in a ripple shape of Teflon with a metal spring. As a result, the valve achieves leakage class VI for applications requiring very tight shut-off.

Retrofit3D components integrate IMI's DRAG technology, which divides flows into a series of right-angled smaller passages. This has the effect of reducing the differential pressure incrementally and increasing control, thus preventing the root cause of the original issue from reoccurring. The Retrofit3D upgrade increases the number of pressure-reducing steps in the valve four-fold, significantly increasing its potential longevity.

Bertrand Maillon, Retrofit3D Business Leader at IMI, said: "This project showcased an advanced use of our Retrofit3D technology, offering more than just a replacement trim - it delivered a substantial enhancement in valve performance. Additive Manufacturing enables unparalleled design flexibility, and when paired with innovative engineering, we empower our customers to boost the reliability and performance of their in-service valves - even in cases like this one, where the original valve design didn't include a disk stack.

"Our customers are under pressure to maintain performance while managing cost and emissions. Retrofit3D provides a clear route to do both - offering a faster, more sustainable way to upgrade legacy valves."

A 2023 life cycle assessment of Retrofit3D undertaken by Ricardo, the environmental and engineering consultancy, found that depending on valve size, the use of this additive manufacturing technique offers a reduction in environmental impact of between 85% and 96% versus traditional valve replacement.

Bertrand added: "Our customers are under pressure to maintain performance while managing cost and emissions. Retrofit3D provides a clear route to do both - offering a faster, more sustainable way to upgrade legacy valves."