Posted to News on 17th Aug 2022, 11:55

Inductive sensors prove a ‘jack of all trades’ in bridge construction

When a specialist assembler of prefabricated bridges needed a rugged sensor for position sensing on its hydraulic cylinders, it turned to Contrinex.

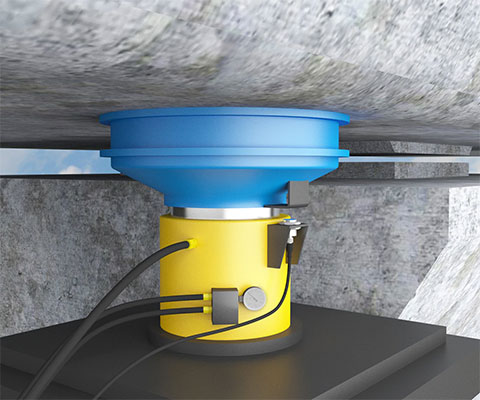

Prefabrication is increasingly common in civil engineering, with for example bridges being constructed from prefabricated bridge elements lifted by mobile cranes onto support columns. To adjust the height of the bridge beams for assembly, heavy-duty hydraulic cylinder jacks support the ends of each beam.

Each jack has a metal bracket mounted onto the side of a bearing plate, which is mounted on the end of the ram and distributes the load onto the bridge section. During a lift operation, when the ram lifting the section, reaches the desired height, a sensor detects the position of the target halting the ram.

One specialist assembler of these prefabricated bridges required a rugged sensor which would reliably and accurately detect the flag on the cylinder independent of weather conditions. Contrinex’s 500 Series of inductive sensors were selected because of their high-performance, industry-leading sensing range and also because they are mechanically robust and able to withstand harsh outdoors conditions. Highly reliable and rated to IP67, these units retain their accuracy across a wide temperature range.

The 22mm sensing distance of the embeddable M30-diameter sensor was selected for the application. It’s chrome-plated brass body with PBTP sensing face and vacuum-encapsulated electronics enabled it to excel in the hostile environment, providing fully contactless operation.

The specialist lifting hydraulic cylinder jacks accurately position the prefabricated bridge sections, with a single bridge section utilising up to 20 jacks. Each jack has a 1,000 tonne capacity and a stroke up to 30mm. Historically, engineers checked the position of each cylinder manually, which was both time-consuming and subject to human error, but previous trials with sensors were unsuccessful because they were not sufficiently robust, needed frequent adjustment or replacement, or had inadequate sensing distances.

A prime requirement is for a simple, contactless system which is reliable to provide extended maintenance intervals, to be considered a fit-and-forget solution. The sensors need to be mechanically robust and able to withstand prolonged exposure to the harsh outdoor conditions of a construction site. The cylinders are commonly exposed to water, mud and dirt, and may also be subjected to mechanical shocks and vibration.

Contrinex 500 Series inductive sensors delivered a cost-effective solution that satisfied the customer’s requirements for a simple, fit-and-forget system in this application.