Posted to News on 23rd Mar 2022, 13:05

Inline 3D profile measurement systems for metal processing

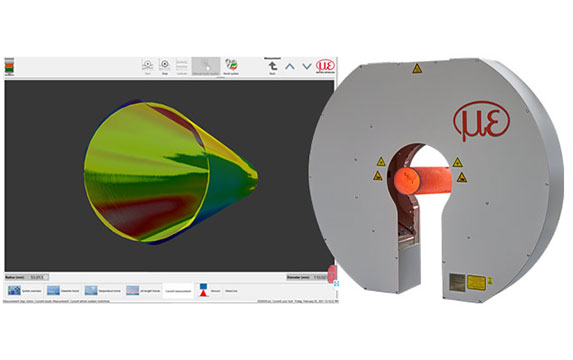

Micro-Epsilon has introduced a range of inline 3D profile measurement systems for the geometrical inspection of long products in metal processing. Depending on the application and profile shape, the measurement systems can be equipped with either ThruBeam sensors, red laser profile scanners or blue laser profile scanners from Micro-Epsilon, to provide the optimal solution for the application.

Long strip products such as profiles, billets and tubes, which are produced by rolling, drawing or forging, often have complex cross-sectional geometries. The new dimensionCONTROL Metal Profile Gauge (MPG) measuring systems from Micro-Epsilon have a compact, horseshoe-shaped design that allows them to be easily integrated directly into metal processing lines, including harsh hot rolling environments. Fully automatic calibration compensates for any potential temperature-related long term drift of the mechanical structure, resulting in a reliable inline measurement system for process control of hot and cold rolled products.

Inside the dimensionCONTROL MPG frame are six laser profile triangulation sensors and a fully automated calibration system. The lasers project straight lines onto the surface to be measured. These lines from each sensor are combined to provide a complete profile around the circumference of the target. The basic calibration of the sensor serves as a reference to convert the deviation into real/actual measured values. Pneumatic protection of sensor optics and optional water cooling is available for harsh, hot environments.

Typical applications for dimensionCONTROL MPG systems include hot and cold rolled long strip products, blooming and finishing mills, where the systems can measure both ferrous (iron, steel) and non-ferrous (aluminium, zinc, alloys, etc.) metals. Positioned at various points along a rolling line, dimensionCONTROL MPG systems acquire and log measurement data to provide essential information to support 100% process control, quality assurance and good/bad inspection decisions, helping to reduce set up time (tool changeovers) during product changes.

The dimensionCONTROL MPG system generates real 3D data with which the key dimensions of the target are calculated. The systems are available with Micro-Epsilon’s comprehensive software package for monitoring and optimising production. A variety of communications interfaces are available for linking the measurement systems with production control systems. All dimensionCONTROL systems can be fitted with non-contact infrared temperature measurement sensors (pyrometers) to provide additional information on the material temperature and can be logged alongside other key measurement parameters.

No. 1 Shorelines Building

Shore Road

CH41 1AU

UNITED KINGDOM

+44 (0)151 355 6070