Posted to News on 26th Oct 2021, 00:00

Innovative compressor hits high efficiency levels with specially designed motor

Looking to revolutionise compressor design, engineering technologies specialist Lontra designed a machine that is inspired by the piston and cylinder found in combustion engine powered cars.

Essentially, the Lontra machine uses the piston and cylinder, before wrapping the cylinder around into a doughnut shape, ensuring the two ends meet. The two ends then separate by a rotating disc, enabling the piston to become a blade. Never seen before, Lontra now has a raft of patents for this new geometry.

Early testing, in the water industry, has showed electricity savings of over 21 per cent against competing machines, while a recent trial of Lontra’s latest machine for the pneumatic conveying sector – blowing various solids through pipes – has shown savings of up to 34 per cent against a market leading competitor.

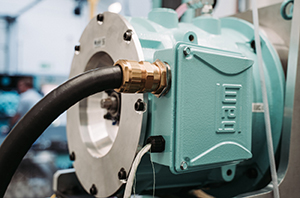

To help achieve this, Lontra contacted Weg to design a special motor for the LP2 Blade Compressor – with maximum international energy (IE) efficiency class standard. This is Lontra’s first industrial blower, involving Weg supplying and specifically manufacturing a WMagnet IE5 ultra-premium permanent magnet motor, rated at 80kW, 2500rpm, constant torque and with hollow shaft – achieving 97 per cent efficiency levels across the entire speed range. The motor is shaft mounted reducing further losses in the system, increasing the overall efficiency of the compressor.

Under the current European efficiency regulations, electric motors must now reach the IE2, IE3 or IE4 efficiency level depending on their rated power and other characteristics. For instance, three-phase motors with a rated output between 0.75kW and equal to or below 1000kW, must have reached the IE3 level by July 2021. Motors between 75kW and 200kW must also meet the IE4 level as of July 2023.

However, Lontra’s new compressor uses a specially designed IE5 electric motor, surpassing current requirements. The IE5 permanent magnet motor was chosen not only for its high efficiency, but because it generates less heat in the rotor and has a steadier temperature due to it being liquid cooled, reducing the likelihood of overheating.