Posted to News on 1st Sep 2021, 00:00

Intertronics busts the 365nm myth

To help businesses looking to adopt LED UV curing in their assembly processes, adhesives specialist Intertronics has launched a new whitepaper: Moving to UV LED curing, the 365 nm myth — a dance between physics and chemistry. The comprehensive whitepaper gives an overview of UV curing materials and technology, to provide the reader with insight into the difference between mercury arc and LED UV curing and guidance of how to manage this in their own processes. The whitepaper is available for free on the Intertronics website here.

UV curing adhesives, coatings and sealants are popular due to their fast, on-demand curing. These materials comprise monomers, oligomers, thickeners, adhesion promoters, other additives, and a small proportion of photoinitiators. Cure is initiated when the correct light hits the photoinitiators, which split and create free radicals, initiating and accelerating a crosslinking process. Supplying the appropriate light energy is essential to a fast and complete curing reaction.

Adhesives and most materials thicker than 50 microns require long wave UV-A (315-400 nm), because it can penetrate and provide depth of cure. This long wave light has historically been provided by UV mercury arc lamps, which generate a broad-spectrum output, ranging from UV-C to the visible light range. These lamps have a peak at 365 nm near the middle of the UV-A range, which is the strongest — but not the only — light energy.

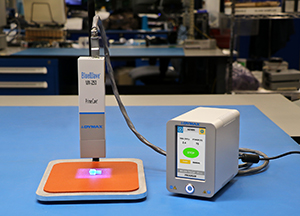

More recently, manufacturers have been turning to LED UV curing lamps, which have a similar output intensity to mercury arc lamps but have a very different output in terms of wavelengths. LED UV curing lamps produce very narrow spectrum light; manufacturers can select the wavelength output — 365 nm, 385 nm, 395 nm, and 405 nm are all common.

“Many product data sheets for UV curing light adhesives and materials suggest they need to be cured with 365 nm UV light, or show an example cure time with intensity measured at 365 nm,” explained Peter Swanson, managing director of Intertronics. “The implication is that the materials require 365 nm LED lights to cure. This whitepaper provides detailed insight into UV curing, explaining the science behind the 365 nm myth, and the potential benefits of using a longer wavelength LED lamp.

“Adhesives designed to cure with broad spectrum light typically react with a wide range of light across the spectrum,” added Swanson. “An adhesive formulated to cure with broad spectrum UV light might react very differently if cured with narrow spectrum LED light, and the final characteristics might not be as stated on the datasheet. We encourage manufacturers to consult with adhesives specialists with experience using different kinds of lamps when switching from broad spectrum to LED UV curing, as their advice can be time-saving and invaluable.”