Posted to News on 20th May 2025, 09:00

KABELSCHLEPP automates waste materials management at AGCO Fendt

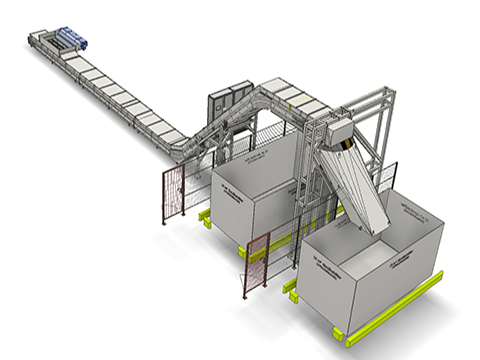

Maximum productivity requires not only precision manufacturing processes, but also smooth disposal of the generated waste materials. This is exactly where the new, fully automated waste disposal solution from KABELSCHLEPP Hunsborn comes in, which has just been successfully commissioned at the factory of agricultural machinery manufacturer AGCO Fendt in Asbach-Baumenheim, Germany.

The intelligent conveyor system ensures a smooth flow of materials - with minimum use of personnel and maximum efficiency.

AGCO Fendt produces the sheet metal parts for its tractors and agricultural machines on a laser blanking system that cuts the material from a continuous coil with precision and high efficiency. The metal waste produced in each step has to be reliably and safely disposed of without interrupting the production flow - five days a week, around the clock.

"The aim was to create an intelligent system that seamlessly integrates into our existing processes," explains Florian Hammel, Project Manager Strategic Plant and Technology Development at AGCO Fendt. "We wanted to increase productivity and minimise downtime while making more efficient use of our resources."

Intelligent waste management with smart details

KABELSCHLEPP, a reliable partner of AGCO Fendt for many years, had the right answer. The specialist for conveyor and guideway protection systems (CAPS) designed a fully automated solution for the laser blanking system that independently and reliably transports the sheet metal cutoffs from the production workshop to an adjacent container building, where it disposes of them in two skips with fill level optimisation.

"The conveyor belt with its own control system and the individual skips, which ensure optimum transport within and outside of the company, are central elements of the recycling process," explains Jorg Kubina, Project Engineer Sales at KABELSCHLEPP. "This enables us to increase the value of the scrap, meaning that the investment pays off."

The interface communication with the laser cutting system additionally supplies Fendt with all the required information for its process data management. Last but not least, the customer benefits from comprehensive project support, including a safety concept, control system, installation, and commissioning, as well as from the service availability over the entire service life of the system.

Reducing resource consumption is becoming ever more important. Metal scrap is a valuable raw material in the recycling industry. The conveyor systems supplied by KABELSCHLEPP for the (central) disposal of waste materials at the factory and for separating different materials help to increase the value of the scrap.