Posted to News on 2nd Jun 2023, 15:30

Levelling the playing field between industrial robot and cobot palletising

See Omron at MachineBuilding.Live, 4 October 2023, on stand 44

Omron recently launched its new TM20 collaborative (cobot) robot with a payload of 20kg, whilst keeping its small footprint and providing a reach of 1.3 metres, making the new cobot ideal for tasks such as palletising.

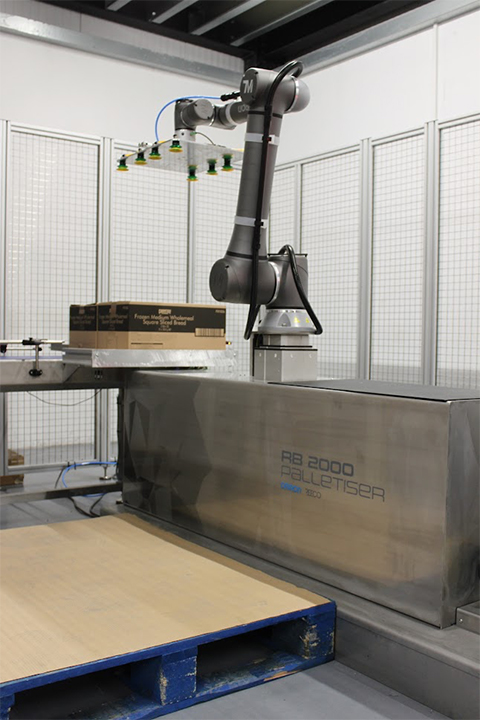

Recognising the potential of the TM20 and the new opportunities it could bring, Reeco a specialist in the manufacturer and delivery of a wide range of palletising solutions and an official UK solutions partner of Omron, was quick to adopt the TM20 and expand its palletising offering. The new RB2000 palletiser is a 20kg payload, cost-effective, market ready solution which makes end-of-line robotic automation attractive to producers of all sizes.

With the introduction of the RB2000, Reeco believes that it has now evened the playing field between traditional industrial robot palletising and cobot palletising. Manufacturers of all sizes now have an opportunity to palletise heavier products but maintain the smaller footprint offered by the Reeco RB range thus not using anymore factory space but creating an automation process to help their existing lines.

But what are the options when it comes to automated palletising and the differences between traditional industrial robot palletising and cobot palletising?

Reeco’s Managing Director Lel Rees explains that robot palletising has been a crucial part of the manufacturing industry for decades. These industrial robots are designed to perform repetitive tasks with precision and speed, making them ideal for palletising. However, with the advent of collaborative robots or cobots, the palletising industry has undergone a significant transformation. But what are the differences between traditional industrial robot palletising and cobot palletising?

Traditional industrial robot palletising involves the use of large and heavy robots that are programmed to perform specific tasks. These robots are designed to handle heavy loads and operate at high speeds, making them ideal for palletising large volumes of products. Traditional industrial robot palletising is ideal for applications where speed and precision are critical.

One of the primary advantages of traditional industrial robot palletising is that it is highly reliable. These robots are designed to operate 24/7 without fail, making them ideal for high-volume manufacturing environments. Additionally, traditional industrial robot palletising is highly customisable, allowing manufacturers to program the robots to perform specific tasks.

However, traditional industrial robot palletising also has some significant drawbacks. Firstly, these robots are expensive to purchase and maintain. Additionally, traditional industrial robot palletising requires a dedicated space to operate, which can be challenging for smaller manufacturers with limited space

Collaborative robots on the other hand are designed to work alongside human operators, performing repetitive tasks that are either dangerous or tedious. Cobots are smaller and lighter than traditional industrial robots, making them more flexible and easier to deploy.

Cobots are also designed to be easy to program, enabling operators to quickly reprogram the robot to perform a new task.

Cobot palletising is ideal for manufacturers with limited space. Cobots are designed to be flexible, allowing them to work in tight spaces and perform a wide range of tasks. Additionally, cobots are designed to be safe to work alongside human operators, reducing the risk of accidents and injuries.

Cobot palletisers are very cost-effective. Cobots are significantly less expensive than traditional industrial robots, making them accessible to smaller manufacturers. Additionally, cobots are easy to program, reducing the need for specialised programming skills.

Traditionally, cobots have been limited to the payload they can pick up compared to traditional industrial robots, however with the introduction of 20kg cobot, this has now levelled up the capabilities when compared to an industrial robot. A cobot palletiser that can lift 20kg can be programmed to perform a variety of tasks, making it a versatile addition to any manufacturing facility. It can be programmed to work with different types of products, pallets, and packaging, providing greater flexibility than a human operator.

Garry Lewis, Market Development Manager of Omron concludes, a cobot palletiser that can lift 20kg can provide significant benefits for manufacturing facilities. It can increase efficiency, improve safety, provide cost savings, offer flexibility, and improve product quality. As automation continues to transform the manufacturing industry, cobots are poised to play an increasingly important role.