Posted to News on 8th Jul 2022, 08:44

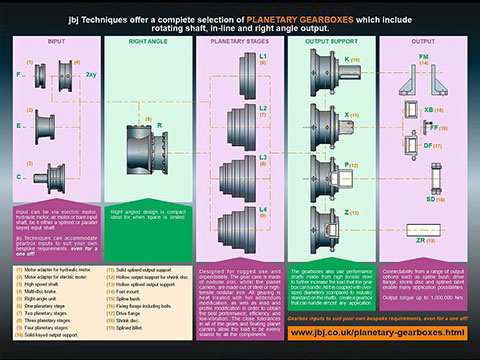

Planetary gearboxes include rotating shaft, in-line and right angle output

jbj Techniques offers a complete range of planetary gearboxes in a modular system that encompasses a range of technical specification values.

The gearboxes are available in 32 sizes, with output torques up to 1,000,000 Nm and transmissible power up to and above 550 kW. Ratios extend from 3:1 to over 3,000:1. Other features include:

- High efficiency, up to 98.5% per stage.

- Full planetary in-line and combined Gleason-planetary right-angle units available.

- 1 to 4 reduction stages, on request 5 stages.

- Optional spring applied-hydraulically released multi-disc brake.

- Flange, foot and shaft mounting versions, bare shaft output available.

- Output shafts include solid keyed, solid splined, hollow splined or for shrink disc mounting.

- Vast range of accessories for the low speed shaft: drive flange, splined bushing, slew pinion, splined rod, shrink disc, torque arm.

- Broad selection of input adaptors to suit standard electric motors both IEC and NEMA, air and hydraulic motors, male input shafts for mechanical linkages.

Designed for rugged use and dependability, the gearboxes feature a gear case made of nodular iron, whilst the planet carriers are made out of steel or high-tensile nodular iron. All gearing is heat treated with full addendum modification, as well as lead and profile modification in order to obtain the best performance and efficiency, as well as low-vibration. The close tolerances in all of the gears and floating planet carriers allow the load to be evenly shared by all the components.

Spline profiles on the gears allow them to handle even larger loads. The all-roller bearing design for the planet gears allows for greater efficiency and superior start-up torque.

The gearboxes also use performance shafts made from high tensile steel to further increase the load that the gearbox can handle. All this coupled with over-sized diameters (compared to industry standard) on the shafts, create a gearbox that can handle almost any application.

Click here for more information.

28 Trowers Way

Holmethorpe Industrial Estate

RH1 2LW

UNITED KINGDOM

+44 (0)1737 767493