Posted to News on 29th Nov 2021, 00:00

Press-N-Lok pin in electric vehicle charging handle

When an automotive manufacturer required a permanent fastener to secure two halves of the electric vehicle charging handle, it turned to SPIROL.

Previously, eight screws had been used to secure the two outer housing components of a plastic charging handle for electric vehicles. The manufacturer decided it no longer wanted the device to be serviceable due to warranty issues related to consumer inflicted damage to internal components. Furthermore, the manufacturer had been experiencing relatively high scrap rates during assembly due to the screws stripping the plastic host.

As a result, it was looking to replace the screws with permanent, tamper resistant fasteners that also supported lean manufacturing.

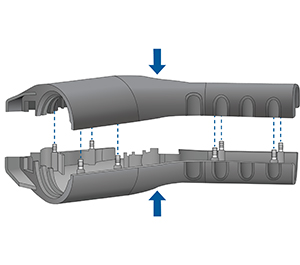

SPIROL Engineering recommended replacing the conventional screws with its Series BP100 Press-N-Lok pins. These solid pins have barbs that provide high retention in plastics, and they are designed to be concealed within the final product after the assembly process is complete. The plastic housing could no longer be separated without visible damage to the charging handle. Therefore, the manufacturer eliminated warranty expenses and activities related to damaged internal electrical components. Additionally, the new electric vehicle charging handle had a sleek, luxurious appearance now that the fasteners were no longer visible.

Press-N-Lok pins are post-mould installed after the plastic has cooled in two stages. First, press the pins into one half of the plastic housing. Next, align the other half of the housing with the exposed pins and press into place. As the pins are pressed into the plastic, the barbs displace the plastic host material. After installation, the plastic naturally backfills behind the barbs to lock the pins in place. This simplified the assembly process for the manufacturer and eliminated scrap events associated with the installation of the screws.

SPIROL engineers are always on hand to review your application requirements and work with your design team to recommend the best solution at the lowest total assembly cost. One way to start the process is to select ‘Pinning Applications’ in SPIROL’s ‘Optimal Application Engineering’ portal.

Many other applications can be reviewed in the private area of SPIROL’s web site. In addition to application examples, registered users gain access to convenient online services and information not available on our public website.