Posted to News on 23rd Jun 2022, 14:50

Reliable cable guiding on industrial robots

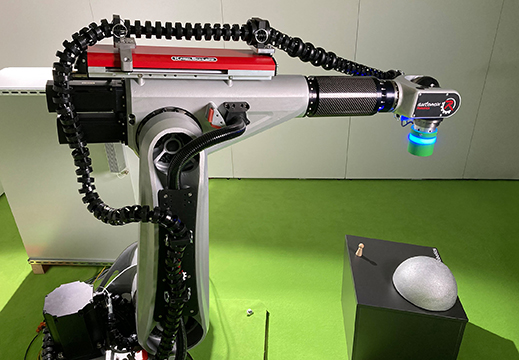

By using the ROBOTRAX cable carrier system in combination with the innovative PBU pull back unit from Kabelschlepp Metool, automation expert Keba Industrial Automation was able to set up a realistic technology demonstrator. Reliable cable guiding was a key element of success.

International automation expert for machine-integrated robots, Keba Industrial Automation, uses its latest demonstrator to highlight the opportunities of creating a digital twin of an industrial robot. To illustrate the corresponding applications, an industrial robot with a versatile tool simulator was set up. Just as in practical application, a multicore cable had to move along with this tool simulator, reliably and safely guided in the robot work envelope even at the highest travel speeds.

Kabelschlepp Metool provided support for planning and configuration of the ROBOTRAX cable carrier, which is flexible in three dimensions and was optimized specifically for use on industrial robots. Reliable cable guiding in different robot positions and at high speeds was achieved with the PBU pull back unit. The Austrian distributor for Kabelschlepp Metool provided support for the practical optimisation.

“The cable carrier system impressed us with its easy installation and versatile fastening options,” explains Michael Garstenauer, product manager for robotics at Keba Industrial Automation. “In combination with the pull back unit, reliable pretension is ensured along the complete demonstration paths.”

The dreaded knocking of the energy chain against the robot is prevented even at the highest speeds while retaining full freedom of movement. The result is a thoroughly reliable overall solution that is suitable for long-term use.