Posted to News on 4th Mar 2022, 15:39

Resin-based 3D printing technology can unlock manufacturing autonomy

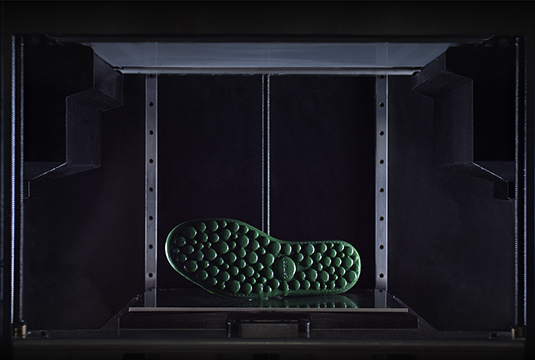

BCN3D has announced a new 3D printing technology to advance alongside its FFF solutions: Viscous Lithography Manufacturing (VLM). This technology has been derived to specifically address BCN3D’s vision of unlocking manufacturing autonomy, where all manufacturers can experience full control over every stage in their production processes with AM solutions.

The company says that using high viscosity resins for better mechanical properties, in combination with this leap forward in productivity and accessibility, ultimately satisfies all demands to unlock manufacturing autonomy.

“If 3D printing is to be the future of manufacturing, and what leads us towards local production, customisation, control of supply chains and sustainability, all the players in the industry should be pushing in this direction. At BCN3D, we think that today is the first step in achieving this goal with the new VLM technology. We want to show 3D printing in a new light so that it becomes the pivotal point of manufacturing,” says Xavier Faneca, CEO of BCN3D.

VLM is a patented lithography-based 3D printing process that laminates thin layers of high viscosity resins onto a transparent transfer film, producing high-performance parts rapidly and affordably. BCN3D says that what distinguishes VLM from other resin technologies on the market is its ability to process resins 50 time more viscous than the industry standard.

The mechanical system allows the resin to be laminated from both sides of the film, making it possible to implement strategies to speed up printing times or even to combine different resins to get multi-material parts and easy-to-remove support structures.

Without a strict low viscosity constraint, chemical companies obtain the freedom to formulate, as a whole new set of ingredients and modifiers can be added in the resin to achieve the desired effect on thermal and mechanical properties. VLM processes resins that obtain three times the amount of impact resistance for rigid materials and a 200% increment in tear strength compared to industry-standard formulations.

Specialty materials company Arkema has been part of the process, through a Joint Development Agreement (JDA) in which the two companies are co-developing new materials capitalising the singularities of VLM to obtain properties that can’t be reached with other resin-based 3D printing processes. As a global key player in the 3D printing industry and a pioneer in designing high-performance photocurable resins, Arkema utilised its experience spanning decades to ensure resins for VLM were of the highest quality.

“Thanks to the proven capability of VLM to manage high viscosity resins, we envision a great prospect to develop new building blocks and enable game-changing formulations to meet applications requirements that have not yet been reached with existing photocure technologies,” says Hélène Egret, Europe 3D market manager at Arkema.