Posted to News on 29th Oct 2020, 00:00

Servo drive system improves productivity during hard times

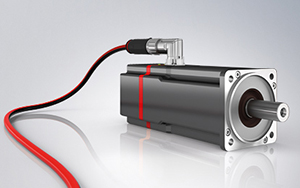

Beckhoff Automation UK has launched the AMP8000 servo system, the latest product in the company’s automation without cabinets range. The AMP8000 features a servomotor with a rear-mounted servo drive for a reduced size and can provide complex motion control with minimal cabling requirements.

Because many factories across the globe have temporarily closed, and many workers have been furloughed, industry is struggling to meet demand. As a result, manufacturers need compact, uncomplicated systems to help maximise productivity. The AMP8000 will find a home on production lines, where its core technological advantages can help improve profits.

The AMP8000 comprises a servo drive directly mounted onto a servomotor, making the design compact and easier to integrate into complex automation machine designs. The rear-mounted drive means that the AMP8000 occupies a similar footprint to a standard servomotor, making it easy to fit into existing machines without modification. The design also improves heat dissipation and reduces motor derating compared to conventional, top-mounted designs.

By relocating the power electronics directly onto the servomotor, the control cabinet only needs to house a single coupling module to supply power to several servo systems. The AMP8000 also makes use of Beckhoff’s EtherCAT P cable technology, combining 24V power and EtherCAT communication into a single standard Ethernet cable.

“As production lines become more densely packed with complex automated machinery, many businesses are encountering a problem in terms of available space,” explains Stephen Hayes, managing director of Beckhoff UK. “Most complex automation requires a vast amount of cabling, which in turn increases the size of control cabinets. These, alongside the growing footprint of automated machinery, occupies space and impacts on output per square metre.

“Now more than ever, the ability to maximise output is vital for industrial businesses. The AMP8000 is designed to help achieve this. In plants, it can significantly reduce cabling requirements due to its EtherCAT P technology and the use of coupling modules. For machine builders, it allows for the development of more complex machinery with smaller footprints and faster site installation time.”

Beckhoff has designed two types of coupling module to accompany the AMP8000. The AMP8620 is a power supply module that allows for safe and direct connection to the mains supply for the servo systems, reducing the footprint and cabling complexity of machinery. This module contains all required circuitry for safe connection and include two EtherCAT P outputs to connect to other modules.

The other module is the AMP8805 distribution module, which provides power and communication to up to five AMP8000 systems using a single EtherCAT P cable each. This allows even complex machines and lines to be connected with minimal cabling and a simple topology.

The Boathouse

Station Road

RG9 1AZ

UNITED KINGDOM