Posted to News on 12th Apr 2024, 14:00

Smart sensors upgrade the measurement of eccentricity during steel-rolling

The precision of Contrinex's inductive sensors has found them used by a customer to measure the roller deformation and eccentricity when bending and forming heavy steel.

Reliable monitoring is essential to avoid potentially significant scrap costs, but taking machines out of service to inspect rollers causes downtime which drives designers to identify real-time monitoring solutions. Contrinex's smart distance measurement sensors (DMS) are able to deliver actionable precision information about the condition of a roller, in real-time, including during rolling operations.

Bending and forming heavy metal plates and strips, particularly in steel or aluminium, requires large-scale investment in industrial rolling equipment with a consequent need to maintain high levels of uptime and productivity. Key to this is monitoring roller deformation and eccentricity, as these are common causes of out-of-tolerance production which can result in significant scrap costs.

Production engineers rely on regular measurement of both parameters to enable corrective action to be taken before product quality suffers. Traditionally, this required machines to be taken out of service to take the necessary measurements, not only putting unwanted time pressure on maintenance teams but also making it almost impossible to detect every occurrence before product defects occur.

The availability of affordable and robust distance measurement sensors from Contrinex which offer exceptionally high accuracy, has enabled designers to identify real-time solutions, eliminating avoidable downtime. They need rugged, high-performance devices, suitable for harsh industrial environments, that communicate seamlessly with modern control systems. Accuracy and reliability must go hand-in-hand with cost-effectiveness, giving an attractive price-performance ratio.

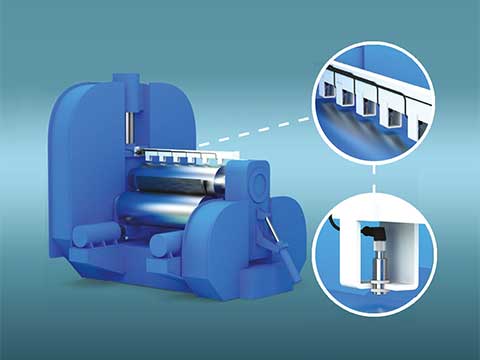

Designers elected to take advantage of Contrinex's high-resolution smart distance measurement sensors (DMS) to upgrade an existing machine. By fitting a semi-permanent, but demountable, crossbar along the top roll of a three-roll bending machine, supporting six stainless-steel M18 DMS sensors at regular intervals, the engineering team implemented a robust, cost-effective solution to the problem.

With the sensors positioned immediately adjacent to the surface of the roller, and with a measurement accuracy to within fractions of a millimetre, they deliver actionable information about the condition of the roller, on-demand and in real-time including during rolling operations. The design of the mounting brackets offers additional protection for the sensors, further protecting these rugged all-metal devices from accidental damage.

The embeddable, one-piece V2A (AISI 303) stainless-steel M18 Smart DMS sensors, have a nominal 10-mm sensing distance for carbon steel, and are highly robust and resistant to vibration and mechanical shock. Capable of measuring both lateral and axial displacement directly, these devices also record cumulative data, including operational cycle count and temperature, with customer-specific alarm thresholds for each parameter programmed into the sensor memory.

IO-Link connectivity, standard across the range, provides an easy industry-standard interface to the central control system for routine process data. During initial calibration, each sensor's configuration is stored automatically on the local IO-Link Master; this allows plug-and-play replacement of sensors should the need arise, without any loss of functionality and without any need for recalibration. Designed with the needs of OEMs and system integrators in mind, smart sensors provide an unobtrusive fit-and-forget solution.