Posted to News on 7th Nov 2006, 00:00

Speeding up pneumatics - easy when you know how

In the February issue of Industrial Technology, we wrote about what can be done to achieve effective speed regulation of a cylinder and the influence of tube length and diameter. It's important to remember when optimising a pneumatic system that it's the whole system that counts, not just changing an individual factor. Fundamental physical relationships also play a key role for the next two factors that influence speed: cylinder energy absorption and valve selection.

Let's consider first the energy absorption at cylinder end positions. Optimising the factors that influence the cylinder leads hopefully lead to a considerable increase in piston speed. This is usually seen as a good thing. However, too high a piston speed - particularly in the end positions - can quickly lead to overloading, as the energy can no longer be absorbed or discharged by the cylinder. The result is high impacts, damage to the cylinder and/or the moving load, whether it be a workpiece, guide, machine, etc. The reason lies in the kinetic energy of the total moving load, where the momentum is the product of mass times the square of velocity. Consequently, if speed is doubled, the cylinder end cap must absorb four times as much energy.

For the highest possible cycle rates it is necessary to create a controlled velocity profile, optimising the acceleration and decceleration throughout the stroke of the cylinder. This is possible using electronically-controlled closed-loop control, providing virtually vibration-free and low-noise final positioning.

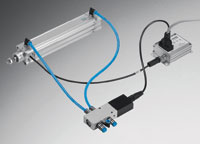

The second factor to consider is valve selection and peripherals. For optimum performance valves must be considered in detail. All too frequently, it is hoped that just by selecting a higher nominal flow rate valve, a higher cycle rate will result. In some cases this may not be true (although the cost goes up), but it is only a part of the answer.

In many machine concepts fieldbuses are used between the central PLC and the decentrally arranged I/O nodes with sensors and actuators. It is easy to overlook that, despite undeniable cost advantages, the sum total of the signal times at controller level can slow down a very fast (pneumatic) system. However, this doesn't have to be the case if the control concept adequately takes this effect into account.