Posted to News on 19th Jul 2018, 00:00

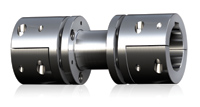

Steel lamina coupling ensures easy assembly and disassembly

The new Rigiflex-N type A-H consists of two hubs, one spacer and two lamina sets which are mounted as a subassembly at the factory. The hubs of the steel lamina coupling are designed as a half shell which allows for radial assembly and disassembly of the overall coupling as a unit. The two semi shell hubs are each mounted via four clamping screws.

“Time-consuming assembly stages like heating the hubs for shrinking onto the shafts and mounting the spacer with the hubs are omitted,” explains KTR product manager Reiner Banemann. “And the disassembly of the coupling does not require any tools such as pullers.” As well as savign time and effort, this means that there is no risk of shafts being damaged, for example by corrosion.

The laminas of Rigiflex-N type A-H are designed as layered waisted sets that are connected with hubs and spacer via positive-locking. Since the focus with the development of the coupling was to comply with API 610 and 671, the spacer is secured by a safety catch. Should the laminas break, the spacer remains within the coupling.

Rigiflex-N type A-H has a compact design along with a high-power density with a low mass moment of inertia. The new steel lamina coupling is available in six sizes for shaft diameters up to 105mm and rated torques up to 2,400Nm. Main applications are pumps in process and chemical industry.