Posted to News on 18th Jan 2022, 00:00

The complete safety solution for access guarding on pallet magazines

Pallet magazines with automatic restart contribute to increased system efficiency. This requires a reliable access guarding system. A new safety solution with induction loops, light curtain and monitored signal sequence satisfies the requirements of revised standard EN 415-4, thereby ensuring maximum safety

Manufacturers and operators of machines and systems must comply with legal regulations. Applicable to manufacturers are, among other things, the Product Safety Act – for operating companies, the Ordinance on Industrial Safety and Health. Standards play another important role. They describe requirements and provide support in ensuring safety at machines and systems. These are, however, not legally binding in Europe.

For manufacturers or operators of machines or systems, type C standards are especially relevant. These are machine-specific safety standards. Among these are EN 415-4 “Safety of packaging machines – Part 4: Palletizers and depalletisers and associated equipment”. The content of the standard from 1997 was significantly revised. In the forthcoming version of the standard, new requirements are placed on manufacturers and operating companies. This also affects the access guarding of pallet magazines with automatic restart.

Up to now, many material transfer stations with automatic restart were safeguarded as follows: electro-sensitive protective equipment (ESPE) secured the access point – if the ESPE is interrupted, the machine and conveyor are stopped. To avoid needing to restart the stopped machine after loading by a corridor supply vehicle, such as a forklift truck, two induction loops are used as muting signals. These are located in the floor in front of the ESPE. When the forklift moves over the induction loops, the electro-sensitive protective equipment is temporarily bridged.

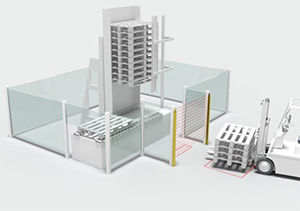

This solution no longer corresponds to the current state of safety technology: The system often ends in a single-channel evaluation logic; as a result, the safety performance is no longer adequate for the given application under certain circumstances. A new type of access guarding for a pallet magazine aims to prevent the entry of persons but simultaneously allow pallets to enter by means of a forklift truck.

Manufacturers and operating companies can now make use of a new solution that is described in the future version of standard EN 415-4. This thereby corresponds to the current state of the art. Two induction loops are also used for this type of access guarding on pallet magazines. The difference to traditional concepts: Both of the induction loops are not located in front of the danger zone.

Instead, one is located outside of the danger zone and the second is located behind the electro-sensitive protective equipment, ie, within the danger zone. The ESPE – the optoelectronic protective device – also remains at the previous position. As before, it separates the traffic zone and danger zone. In addition, there is also a safety system that monitors a defined sequence of signals and initiates the automatic restart.

For this solution, the following technical framework conditions must be implemented: the pallet magazine must be safeguarded at the adjacent areas. A person who passes through the ESPE must not be able to enter other areas of the system unnoticed. This can be ensured mechanically, for example by means of a height limitation. This allows an empty pallet to pass through, but not a person. Alternatively, a second piece of electro-sensitive protective equipment can be installed to detect the entry of a person into the danger zone.

Further, the outer induction loop over which the forklift truck travels requires sufficient space. This is somewhat larger than the inner loop. In addition, the operating personnel must be instructed because this involves an automatic restart. The driver of the forklift truck is responsible for ensuring that no one gains access to the danger zone by moving alongside the forklift truck. If, there is still a person in the inner area at this time, the driver must not drive out, as the pallet magazine will otherwise be started. Alternatively, this risk can also be eliminated by means a safeguard that provides stepping behind protection.