Posted to News on 27th Jul 2015, 00:00

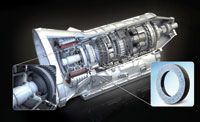

Transmission seal designed with a built in lightning rod

The rise of electric and hybrid vehicles has driven demand for transmission seals that can do more than just seal. The response to this need is a new product that can selectively conduct electric current and thus protect against electrostatic charging.

>Strict CO2 requirements are leading automakers to increasingly offer plug-in hybrid vehicles, which in fact have an internal combustion engine on board but can be driven purely electrically up to 120km/h. The electric motor, running on an operating voltage of about 400V, is generally located on the input shaft of the automatic transmission instead of a hydrodynamic converter.

>At this location, a good seal must do more than protect the electrical portion of the powertrain against contamination by transmission oil. That is because an electric potential can arise within the motor between the housing and the shaft. A conventional seal ring made of elastomers has an insulating effect, however, and would lead to a buildup of electric potential.

>Recognising that seals that can do more than just seal will play a key role in the transmissions of the future, Freudenberg Sealing Technologies presented a new sealing technology for hybrid and electric vehicles at the International VDI Congress 'Drivetrain for Vehicles'. The new conductive transmission seal works like a lightning rod. Electrical current is conducted selectively from the housing to the transmission input shaft via a conductive non-woven attached to the seal, so the electrostatic charge does not even develop in the first place.

>This solution, which Freudenberg Sealing Technologies says is ready for series production, saves the automaker the trouble of separately providing potential equalisation through the use of additional cost-intensive elements such as carbon brushes, which are not wear-resistant. It can be used in plug-in hybrid vehicles as well as in the more simply constructed drivelines for battery-powered vehicles.

>Freudenberg Sealing Technologies also presented innovative sealing concepts for non-electrified vehicle transmissions. In these cases, a seal that can do more than just seal plays an important role as well. For example, the rotational speed at the transmission input shaft is measured for the transmission's control system. This is important to make shifting as smooth as possible, for example.

>Today, a separate rotational sensor (encoder) is generally used for the measurement. It determines the rotational speed through the use of magnetised segments. Freudenberg Sealing Technologies has now developed a shaft seal ring in which the magnetised segments are applied directly to the elastomer and thus provide precise information on rotational and angular velocity. This saves both labor during mounting and costly installation space at the front facing side of the transmission.

>Freudenberg Sealing Technologies says it is increasingly delivering not just the seal ring but a completely pre-assembled unit as well, consisting of a plastic front cover, the static housing seal, and the shaft seal ring. Unlike a metal part, the seals do not have to be mounted separately. They are moulded right along with the plastic, which not only saves production time and prevents assembly errors but also, the company asserts, leads to weight savings of up to 50 percent.

>With transmissions becoming increasingly compact and complex, Freudenberg Sealing Technologies says it is shifting into high gear with low-friction, weight-saving sealing technology that combines industry's requirements for reductions in fuel consumption and weight with high reliability and long operating life.