Posted to News on 19th Oct 2021, 00:00

What is condition monitoring and why do I need it?

Condition monitoring uses sensors to monitor equipment and give an early warning of failure. This dramatically reduces costs by allowing planned maintenance instead of catastrophic failure and production loss. But often vibration and temperature monitoring is seen as too expensive or too complex for small to medium businesses.

In order to bring effective, 24/7 condition monitoring to all sizes of business Turck Banner has introduced a self-contained, pre-programmed, starter kit for vibration and temperature monitoring at less than £600. The kit is designed for the first-time user with everything included to monitor one motor and receive warnings before failure. However, as it uses the same controller as Turck Banner’s large condition monitoring systems there is no compromise in performance, or the capabilities to expand into a large scale monitoring system integrating in to existing local and cloud networks.

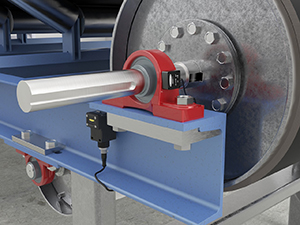

The IP67 control module does not require a cabinet and connects wirelessly to the sensor, which is easily mounted on a motor, pump or fan, with the magnetic mounting bracket included in the kit. Once connected, the controller monitors the running vibration and temperature of the motor and sets a baseline operating range. From this baseline the controller intelligently establishes warning and alarm alert levels for this motor.

The current motor condition is displayed on a web interface as a green, amber or red icon, with all the historical data shown at the touch of the icon. The web interface allows remote condition display from any browser on any smart phone, tablet or PC. When this is combined with text alerts, maintenance personnel have instant access to the condition monitoring system whenever they need it.

“This is ‘plug and play’ technology that’s designed to provide condition monitoring information that’s as simple to understand as a car’s ‘check engine’ light,” says Turck Banner UK sales manager Tony Coghlan. “There are lots of brownfield sites where the infrastructure is quite old and where it can be hard to integrate condition monitoring technology. With this solution, we can go to any site and get people consuming data straight away.”

By deliberately not overcomplicating the solution, Coghlan says Turck Banner has made it simple for users to make their maintenance regime proactive and predictive, and the technology is cost-effective for use in sites that could have large numbers of rotating assets. The starter kit has numerous expansion possibilities. Up to 40 wireless sensors can be connected to a single starter kit, the controller is preprogramed for the 40 sensors.

The customer is not locked into the preprogramed cloud configuration. At any time, the controller can be connected to local networks, SCADA, PLCs or other cloud systems. This allows external data gathering, analysis, and integration into existing systems, such as DCS or CMS.